Force and Pressure Sensor Technology to Measure Impact Force

Impact force occurs whenever two surfaces or bodies collide, delivering energy in the form of an instant shock. In the design of a product, device, or piece of equipment, technology to measure and quantify impact force can go a long way in improving the design’s durability, among several other processes.

Impact force occurs whenever two surfaces or bodies collide, delivering energy in the form of an instant shock. In the design of a product, device, or piece of equipment, technology to measure and quantify impact force can go a long way in improving the design’s durability, among several other processes.

You’re more than likely familiar with the mathematical equations to calculate impact force (this Engineering Toolbox post provides a full range of examples), but for certain impact tests, real-time pressure distribution data following a rapid impact event may be a greater need.

Take a head-on collision between two vehicles, for instance; if we know the mass and velocity of both vehicles, we can calculate the impact force of the collision. We can also see clear evidence of the impact aftermath in the form of damage outside and inside either vehicle. But for the automobile manufacturer, it’s critically important to understand the full array of pressure distribution across the entire impact area. Having quantifiable data on the real-time impact sequence can help uncover problem points or weak spots within the vehicle design, whether on the vehicle exterior or within the passenger cabin.

Therefore, depending on the type data you wish to measure from your impact force test, there are certain force measurement technologies that may yield better results than others.

Force Sensor Technologies that Measure Impact Force

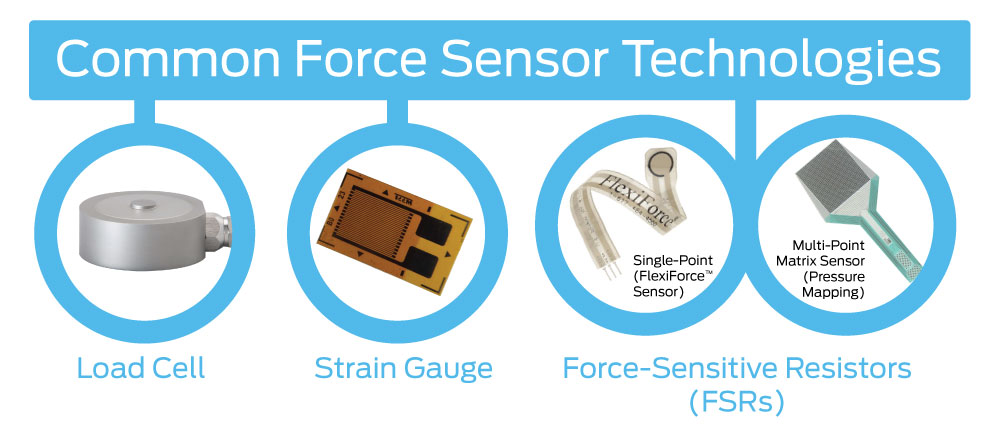

force-sensitive resistors (otherwise known as FSRs), as shown above, are three of the most common force-sensing technologies used to measure impact force.

force-sensitive resistors (otherwise known as FSRs), as shown above, are three of the most common force-sensing technologies used to measure impact force.

Both load cell and strain gauge technologies are accurate impact force measurement sensors, especially if you’re looking to capture data on a very specific point of impact. However, going back to the car crash example, attaching a load cell or strain gauge to a vehicle is not a practical method to capture the in-depth impact force analysis, or pressure distribution information the test truly requires.

One of the key advantages FSR technology has over load cells and strain gauges is their ultra-thin, minimally-invasive form factors that can be customized to cover a larger impact force sensing region. FSRs consist of semi-conductive material contained between two pieces of thin, flexible polyester. As their name suggests, FSRs are passive elements that act as a resistor in an electrical circuit. They come in two different forms – single-point sensors, and multi-point matrix sensors.

At Tekscan, we call our single-point embedded FSRs FlexiForce sensors. We offer a full line of standard off-the-shelf FlexiForce sensors in different sizes and force ranges on our website, but also produce custom sensors for applications including medical devices, consumer products and security/inventory management systems.

Our matrix FSRs are known as pressure mapping sensors. In our I-Scan™ pressure mapping system, a pressure mapping sensor is connected to scanning electronics, which relays pressure data to software via USB. The electronics can scan at speeds up to 20 kHz. The I-Scan system's ability to capture these rapid events allows the user to identify peak forces and the pressure distribution across the sensing array in a clear, digital display.

Examples of FSR Technology in Impact Force Measurement Applications

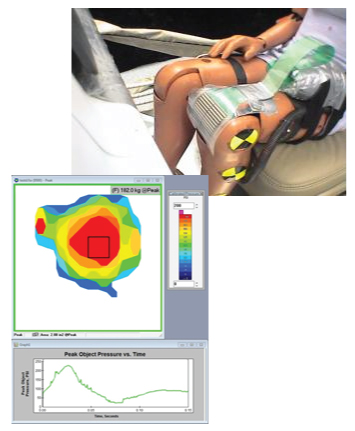

Figure 1: Output of peak pressure on a crash test dummy's knee.#1 - Crash Dummy Impact Force

Figure 1: Output of peak pressure on a crash test dummy's knee.#1 - Crash Dummy Impact Force

In this application, a pressure mapping sensor was used to capture dynamic pressure and impact force exerted on a crash dummy during impact. Using an I-Scan™ force and pressure mapping system, an ultra-thin force-sensitive matrix recorded the output of peak pressure as it occurred at a high speed. The image seen in Figure 1 shows an example of impact force output from a sensor positioned on the knee of a crash dummy.

A matrix pressure sensor can measure high speed impact forces in many configurations, including knee impact with consoles as shown, seat belt forces, and more.

#2 - Impact Force in Athletics

Full contact sports like football, hockey, or rugby, and combat sports including boxing, taekwondo, and mixed martial arts, exhibit impact forces and collisions in a variety of ways. Ultra-thin force sensor technology provides the ability to capture data in ways that do not impact the athlete’s ability to perform. Watch this video to see a few of these applications in action.

|

For other force-sensitive applications in athletics, download this free eBook. |

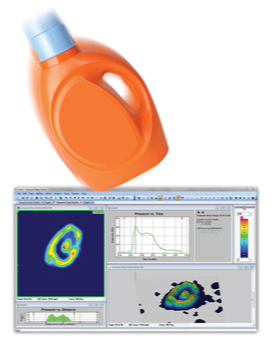

Figure 2: Results from a packaging drop test displays pressure distribution in finite detail.#3 - Impact Force from Packaging Drop Test

Figure 2: Results from a packaging drop test displays pressure distribution in finite detail.#3 - Impact Force from Packaging Drop Test

Knowledge of how a product will react in different drop testing scenarios can help manufacturers determine the best way to pack a product for shipping, and what could happen if the end user were to drop the product. In this test, depicted in Figure 2, a consumer packaging container filled with liquid was dropped onto a pressure mapping sensor from different angles and heights to identify the concentration of pressure.

Looking for Methods to Measure Impact Force? Contact Us Today to Discuss.

Given their thin, flexible form factors, there are truly endless applications to capture impact force between nearly any two surfaces with FSR force and pressure sensing technology. Not sure what is right for your application? Our engineers can help. Reach out and let's begin a conversation.