Advancing Tactile Sensing: From Innovation to Scalable Manufacturing

High Speed Roll Printed Sensor

High Speed Roll Printed Sensor

Tactile sensing has evolved from niche research technology to an essential layer in next-generation smart-system design in energy storage, automotive, robotics, medical devices, and industrial automation. As organizations push for smarter, safer, more connected products, tactile sensors — particularly thin-film, flexible, and surface-mapping sensors — are becoming more essential. These tactile sensors enable engineers to capture surface-level data that more traditional sensing technologies can’t access.

In our latest Electronic Design article, we explore how the industry is transitioning from early-stage innovation to scalable real-world deployment.

This is the third article in our four-part series.

- Part 1 introduced the tactile sensor industry landscape and key growth drivers

- Part 2 discussed multi-modal tactile and temperature sensing and emerging application areas

- Part 3 (this article) focuses on manufacturing maturity and system-level integration

- Part 4 will look ahead at commercial acceleration and long-term adoption trends

Scaling production beyond the lab

The industry is moving toward reliable, repeatable manufacturing for flexible tactile sensors. Advances in printed electronics and automated production equipment are making it possible to produce thin, durable sensing layers at scale — while still supporting custom shapes and flexible form factors. Quality checks throughout the manufacturing process, along with consistent materials and assembly methods, play a big role in ensuring performance stays stable as volumes increase.

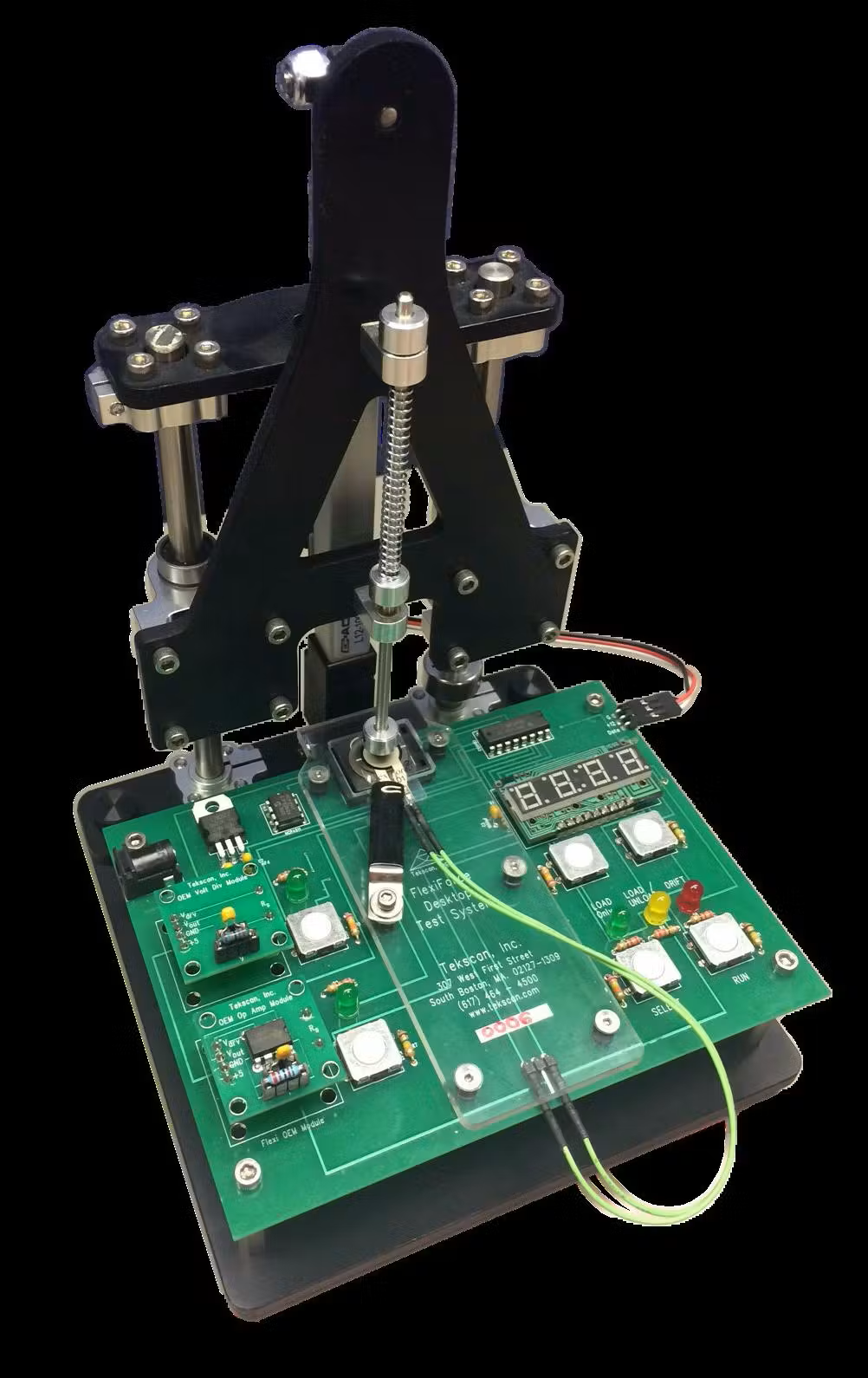

Sensor Testing and Validation

Sensor Testing and Validation

System-level design is key to reliable sensor performance.

To ensure accuracy and repeatability, engineers must consider factors such as:

- Mechanical stack-up and force-transfer layers

- Electrical circuit approaches (e.g., voltage-divider vs. amplifier-based conditioning)

- Calibration workflows, pre-load routines, and environmental testing

- Connector design, routing, and packaging for real-world durability

Addressing these elements early in development builds confidence that the sensor will behave as expected in real environments, not just controlled test setups.

Looking ahead

Tactile sensing is shifting from research to real-world scale. As the technology becomes easier to manufacture and integrate, its value will extend across manufacturing quality, robotics, battery systems, healthcare devices, and more. The result: smarter products and more reliable processes.