Measure and Analyze Impact Force and Pressure Data

R&D teams are often challenged with mediating the effects impact events can have on a product, especially in situations where drops or blunt forces can occur over its use.

Capturing impact data helps R&D teams perform quality control and assurance tests on their product design, ultimately developing a more durable product that customers can use and trust.

|

Force Measurement Applications

|

Pressure Measurement Applications

|

|

Typical R&D Challenges |

||

Quality Control |

Optimizing Product Design |

Optimizing Durability & Safety |

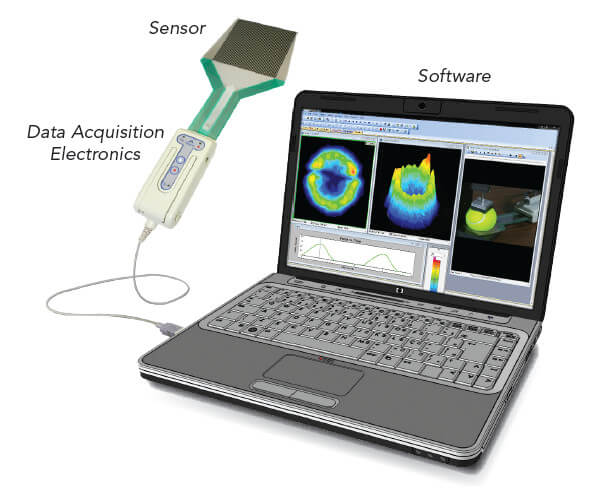

Impact Measurement Solution: I-Scan™

Tekscan's I-Scan™ system has been used by R&D teams of all kinds to test how impact can affect a product over its use. This device, which captures quantifiable high-speed impact data using sensors, can help R&D teams perform quality control and assurance tests, in order to develop a stronger design that can endure drops or accidents over time.

Key System Features

- Measure dynamic pressure and impact force

- Capture multiple frames of data

- Maximum scanning speed of full array: 20 kHz

Watch the video below to learn how pressure mapping systems capture high speed impact data to help engineers design quality products that can withstand drops, crashes, and more.

How Can Our Impact System Benefit You?

Get in touch with us to discuss your impact pressure/force application!