A ‘Uniform’ Seal of Approval: Pressure Mapping Helps Prove Wet-Out Emblem Application Processes on Automobiles

For many of us, the vehicle we drive is a reflection of ourselves. By brand name alone, vehicles represent symbols of wealth, toughness, or environmental responsibility, which makes the decision to purchase one vehicle over another a very personal choice. This is because many automotive manufacturers have developed strong brand profiles through keen marketing tactics including memorable slogans, striking vehicle names, and iconic logos.

When you consider both the mental and financial investment that goes into a vehicle purchase, there may be few things more frustrating than finding a part of the vehicle’s identity has fallen off due to poor manufacturing processes.

In a factory setting, vehicle logos, emblems, or badges applied through a “wet-out” (or “quick wet”) method. In this process, adhesive is applied to the badge, which is then pressed onto a vehicle part using a pneumatic tool handled by an operator, or administered by a robotic system, as it passes through an assembly line.

Uniform and consistent wet-out application is important to ensure that the emblem stays secure to the vehicle. Uneven application on the vehicle can create gaps in the seal, which can cause the emblem to fall of the vehicle over time. Temperature swings in the manufacturing environment can also contribute to stress on the badge. Over time, moisture, vibration, and even forces from automated car washes, all have been known to remove emblems that are applied with an uneven seal.

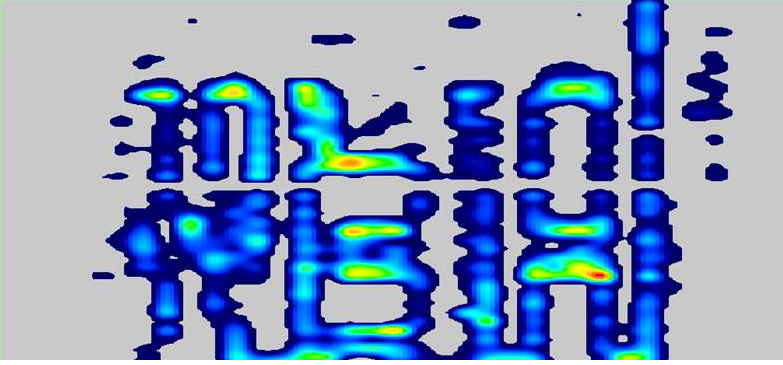

One automobile manufacturer set out to improve their wet-out application consistency by testing pressure uniformity applied by their pneumatic emblem application tool. A pressure mapping sensor connected to a wireless datalogger unit was positioned onto a vehicle door to record pressure distribution across an entire emblem design. With this information, the operator could adjust the position of the pneumatic tool, and also reposition themselves to apply the emblem at the better angle for an even seal.

Figure 1: As this pressure display shows, there is especially higher contact toward the middle of this vehicle emblem, but lesser pressure along the edges.

Figure 1: As this pressure display shows, there is especially higher contact toward the middle of this vehicle emblem, but lesser pressure along the edges.

Not only does this test help ensure the manufacturer’s brand quality and appearance; it also helps protect against potential warranty complications that may occur over the vehicle’s use.

Hover over the icons below to explore other automotive pressure mapping applications: