Battery Webinar Q&A: Your Top Questions, Answered

This post wraps up our four-part interview series with our own Pressure and Temperature Mapping expert, Evan Griffith. Our conversation was based on Evan's recent live webinar on improving battery safety and performance through pressure and temperature mapping.

Throughout this series, we’ve explored the importance of capturing pressure and temperature data during battery formation, what engineers can learn from this data, and how to apply those insights to improve product quality and safety.

Now, we’re closing things out with one of the most valuable parts of any live event: the Q&A. from the audience - the engineers in the field who are working to solve battery design and manufacturing problems every day. Below, our applications expert Evan addresses some of the most common questions engineers asked during the session — and his answers shed light on some of the most frequent challenges in battery R&D and manufacturing.

Q: Are pressure changes caused by cathode expansion or heat?

Evan: In most cases, pressure changes are driven by cathode expansion, particularly during thermal cycling in the formation process. This expansion is what causes pressure to rise inside the cell.

One of the biggest advantages of our system is the ability to pair pressure and temperature sensors. This allows you to verify whether heat is contributing to the pressure changes and identify exactly where the expansion is happening. Having both data points gives you a more complete picture and helps you troubleshoot the root cause faster.

Q: Can these sensors be mounted inside a 300 Ah prismatic cell?

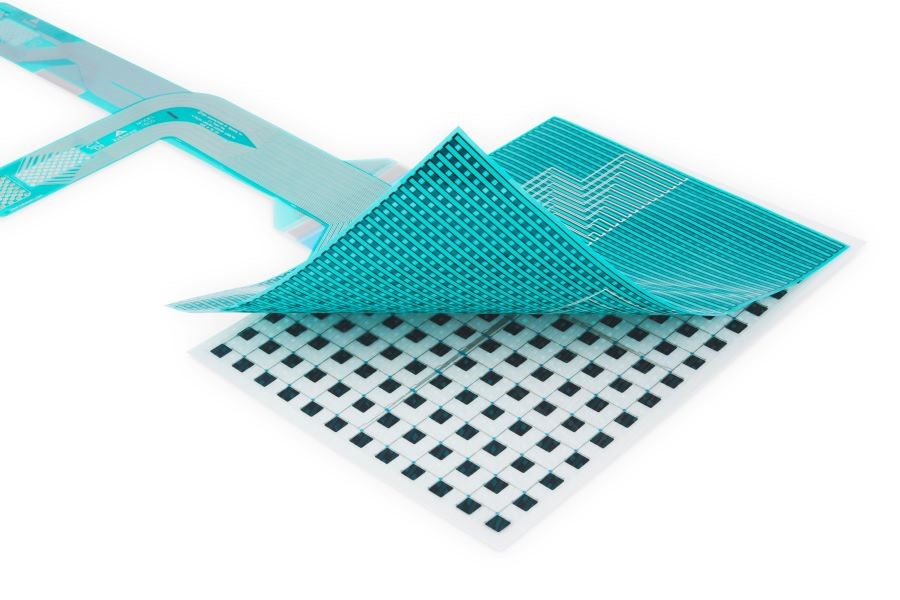

Evan: Most likely, yes — our sensors are designed to be thin, flexible, and trimmable, which makes them well-suited for prismatic cell applications. They can be cut or wrapped to fit many different cell geometries while maintaining measurement accuracy.

When planning sensor placement, it’s important to consider factors such as available space, expected pressure ranges, and operating temperature. Sharing your cell specifications and operating conditions with us allows our team to recommend the most effective configuration and ensure reliable performance in your application.

Q: How sensitive is the pressure sensor to temperature gradients? And does pressure affect temperature readings?

Evan: We’ve done extensive validation to confirm that there is no statistically significant cross-interference.

Even when we simulate real-world conditions — such as stacking a pressure sensor on top of a temperature sensor over a heated plate — pressure does not meaningfully affect the temperature readings. This is because the temperature sensor uses thermoresistive ink that responds only to temperature, not applied force.

This gives engineers confidence that they can collect accurate, independent data from both sensors simultaneously.

Q: How thick are the pressure and temperature sensors?

Evan: Both sensors are extremely thin — approximately 0.18 mm — and are designed to be flexible and minimally invasive.

Our T-800 temperature sensor was created to match the dimensions of our popular 7800 pressure sensor. This means you can overlay them, trim them to size, and use them together without risking damage to the traces — giving you two layers of insight in the same footprint.

Wrapping Up the Series

This Q&A brought forward some of the questions engineers face when working to monitor and control pressure and temperature during battery formation. We hope these answers give you practical insights you can apply in your own process development or troubleshooting efforts.

If you missed any of the earlier posts in the series, you can explore them here:

- Part 1: Why Pressure and Temperature Matter During Formation

- Part 2: What Engineers Can Learn from Pressure & Temperature Data

- Part 3: Applying Insights to Improve Quality & Safety

Have a question of your own? Submit it here and we'll follow up; and we may feature it in a future blog post.

---

Want to see temperature and pressure mapping in action? Watch Evan Griffith’s full webinar for live test demos, real sensor data, and setup tips