Why Pressure Mapping is Becoming Essential in Battery Engineering

Part 1 of our “Impactful Insights” Interview Series with Tekscan’s Evan Griffith

As battery manufacturers race to improve energy density, safety, and performance, mechanical forces inside the cell are getting more attention. In this new interview series, we speak with Evan Griffith, Product Manager at Tekscan, about the role of pressure—and now temperature—mapping in shaping the future of battery technology.

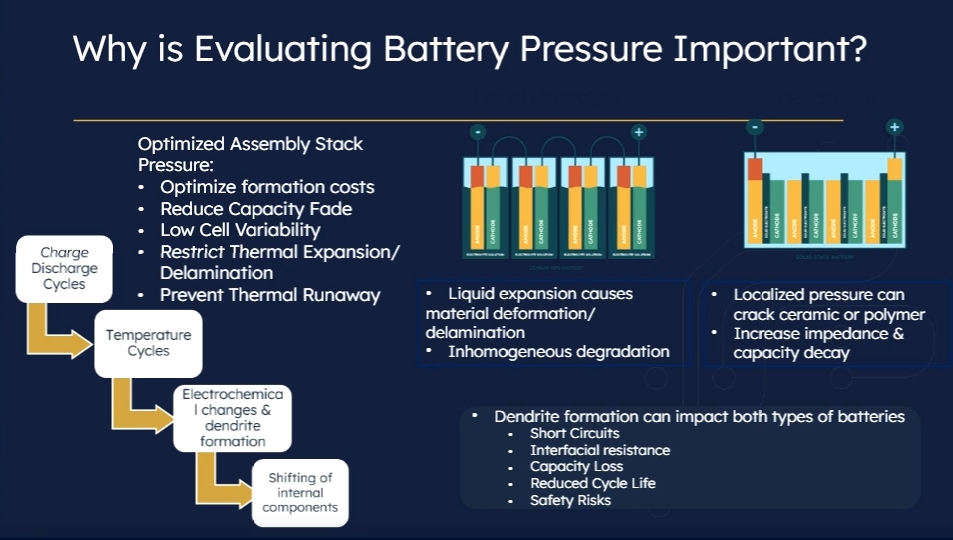

Q: Evan, let’s start with the big picture. Why should battery engineers be paying attention to pressure?

Evan: Pressure is more than just a mechanical force—it’s a signal. As lithium-ion batteries go through charge and discharge cycles, they swell and contract. These internal mechanical shifts can affect everything from SEI layer formation to long-term reliability. If the pressure isn’t distributed evenly—or if it's too high or too low—it can lead to safety issues, degraded performance, or early failure. And unless you're mapping pressure across the full surface of the cell, you might not even see the problem coming.

Q: So how are most teams measuring pressure today?

Evan: We see a mix. Some use load cells to measure force at a single point, others use pressure-sensitive film, which gives a one-time snapshot but lacks data over time. What we offer with pressure mapping is a thin, flexible sensor that gives you a live view of the pressure distribution—across the whole battery surface and throughout the testing cycle. You can watch pressure shift in real time during charging, discharging, or formation.

Q: Where in the battery lifecycle is this most valuable?

Evan: A lot of our users start in R&D because it’s easier to integrate sensors into development setups. If you’re designing a new cell type or experimenting with formation protocols, pressure mapping helps validate stack pressure, fixture design, and material behaviors early on. That said, we’re seeing more use on the manufacturing floor too—for quality checks, inline validation, or even embedded sensors that stay in the fixture during production.

Q: Can pressure mapping really detect hidden problems?

Evan: Absolutely. One example comes from a study where researchers used load cells to identify an ideal “average” stack pressure. But when they added our pressure mapping sensor, they found localized high-pressure zones—likely from manufacturing inconsistencies. Those cells degraded much faster. So while the average pressure looked fine, the actual distribution was uneven. That kind of insight can be game-changing.

Q: What’s the learning curve like for teams adopting this?

Evan: Pretty low. Our sensors are thin, flexible, and minimally invasive. They fit between battery layers or into fixtures with very little modification. You can start capturing real-time pressure data almost immediately, and we provide all the scanning electronics and software you need. That simplicity is one reason we’ve seen so much adoption in the battery space.

What’s Next in the Series

Up Next: In Part 2 of our interview, Evan explains how pressure mapping helps engineers optimize stack pressure and SEI layer formation – and why that matters for performance and safety.