How Stack Pressure Influences SEI Layer Formation

Part 2 of our “Impactful Insights” Interview Series with Tekscan’s Evan Griffith

In Part 1 of our interview, Tekscan Product Manager Evan Griffith shared how pressure mapping gives engineers a real-time view of internal battery dynamics. Today, we go deeper into one of the most important and often overlooked mechanical factors in battery performance: stack pressure.

In this second installment of our Impactful Insights series, Evan explains how pressure distribution during formation affects SEI layer quality, cell degradation, and overall battery safety—and why a more complete view of pressure is changing the way engineers optimize cell design and formation protocols.

Q: Evan, for readers less familiar, what exactly is stack pressure and why does it matter?

Evan: Stack pressure refers to the force applied to a battery cell—typically by its housing or fixture—during assembly and formation. That pressure needs to be "just right." If it's too low, cells can expand excessively during charging, potentially leading to internal defects or thermal runaway. If it's too high, you can damage internal components or reduce long-term performance.

The goal is to maintain uniform, optimized pressure across the full surface area of the cell—not just on average, but in every localized region.

Q: What role does stack pressure play in SEI layer formation?

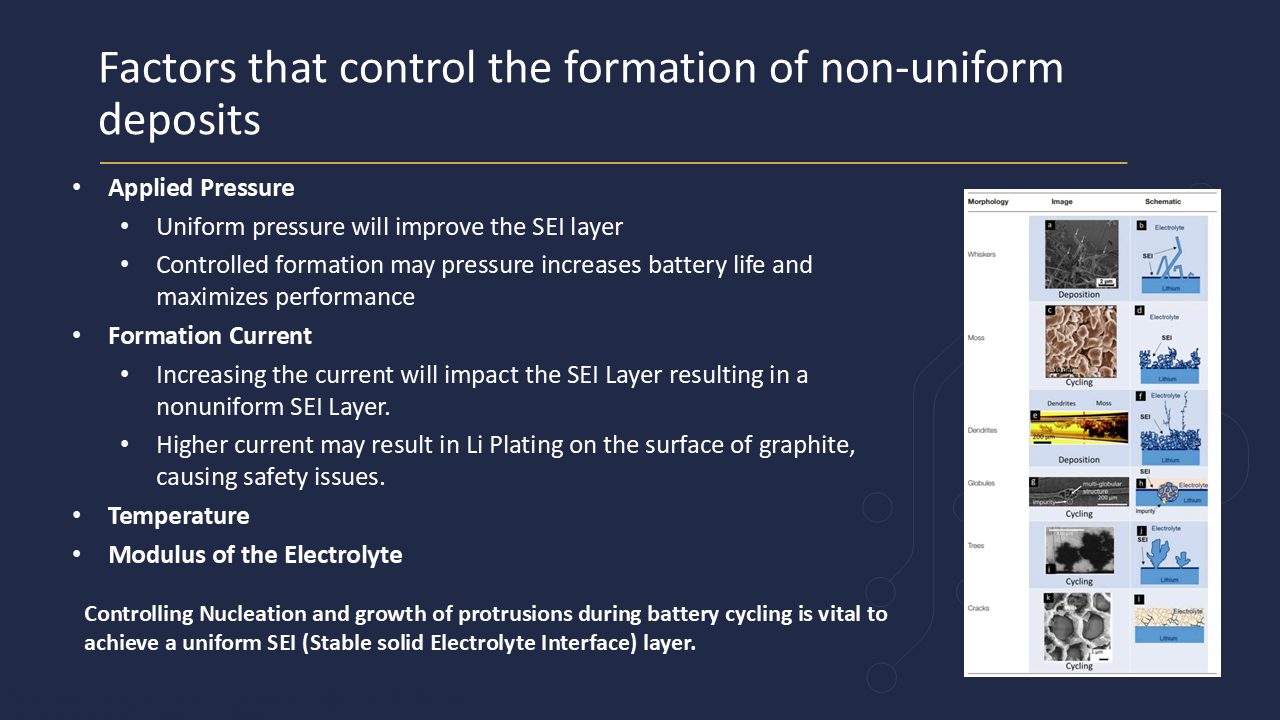

Evan: The SEI, or solid electrolyte interphase, forms during the initial charge cycles. It’s a passivation layer that protects the anode and stabilizes the electrolyte interface. If the pressure during formation isn’t uniform, the SEI layer can develop inconsistencies—like dendrites or non-uniform lithium deposits—that shorten battery life or cause internal shorts.

Mapping pressure helps ensure that you're applying a consistent force across the entire cell during formation, which promotes a stable, high-quality SEI layer.

Q: What’s the takeaway for battery engineers?

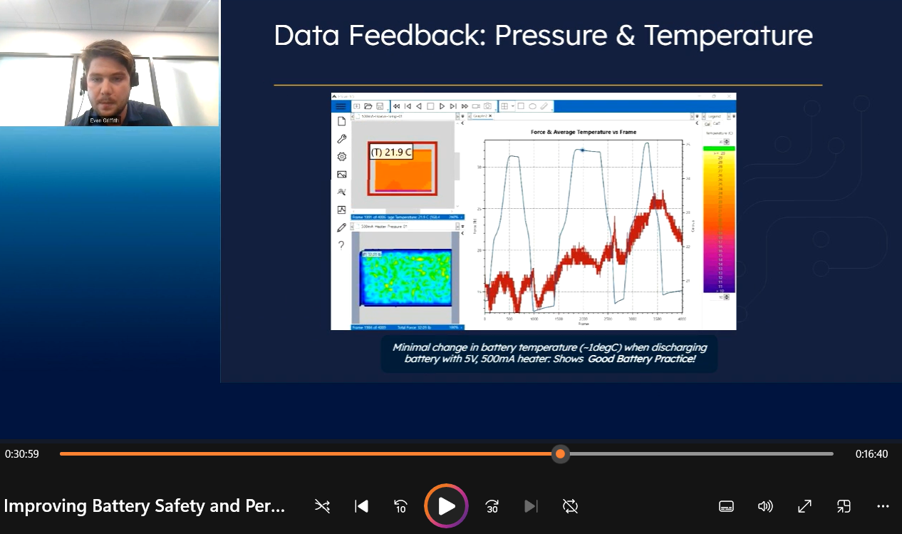

Evan: Stack pressure isn’t just a fixture design consideration—it’s a variable you can measure, optimize, and control to improve battery life, stability, and safety. And when you combine that with temperature mapping, you get a multidimensional view of what’s happening during those critical formation steps.

With today’s tools, engineers can move from “monitoring” to truly engineering pressure and thermal conditions for the best possible results.

See it in Action – Watch the On Demand Webinar

Want to go deeper? Watch Evan Griffith’s full presentation, including real-life examples of charge/discharge testing, fixture setups, and sensor data analysis:

Improving Battery Safety & Performance with Pressure and Temperature Mapping

Now available on demand — watch anytime!

---

Part 3:

How Tekscan’s new temperature mapping solution works, and what it reveals about thermal behavior during formation and cycling.