Can Tekscan sensors be cut or trimmed?

Question: Can Tekscan sensors be cut or trimmed?

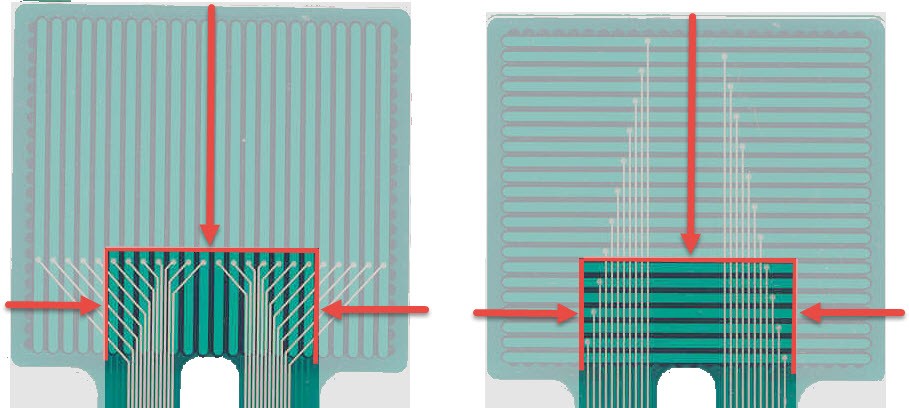

Answer: Yes, some of our sensors can be cut or trimmed to smaller sizes or shapes, or even punctured for secure placement. The model 4205 (pictured), model 7800 pressure sensor and T800 temperature sensor are designed to be sized for custom embedding in battery placements or other tight spots.

Tips for trimming:

Tips for trimming:

The rows and columns are connected through silver dots and traces on the surface of the sensor. If you trim the sensor, a row or column will remain active so long as the silver dot and silver connecting trace remain intact and connected to the handle.

Based on this photo, you can trim up to 15 rows from the distal end of the sensor before you reach the column trace connections. And you can trim up to 5 columns from either side before you reach the silver connections to the rows.

Consult with a Tekscan engineer if you aren't sure if your sensor is trimmable or how to do it. Cutting through the sensing element will short the sensor!

---

The ability to trim for shoe size is one of the most important advantages of our in-shoe F-Scan™GO sensor, which can be trimmed to fit any shoe size up to a men’s size 14.

Tips for trimming the F-Scan GO sensor can be found in the manual, or HERE.

Link to this FAQ