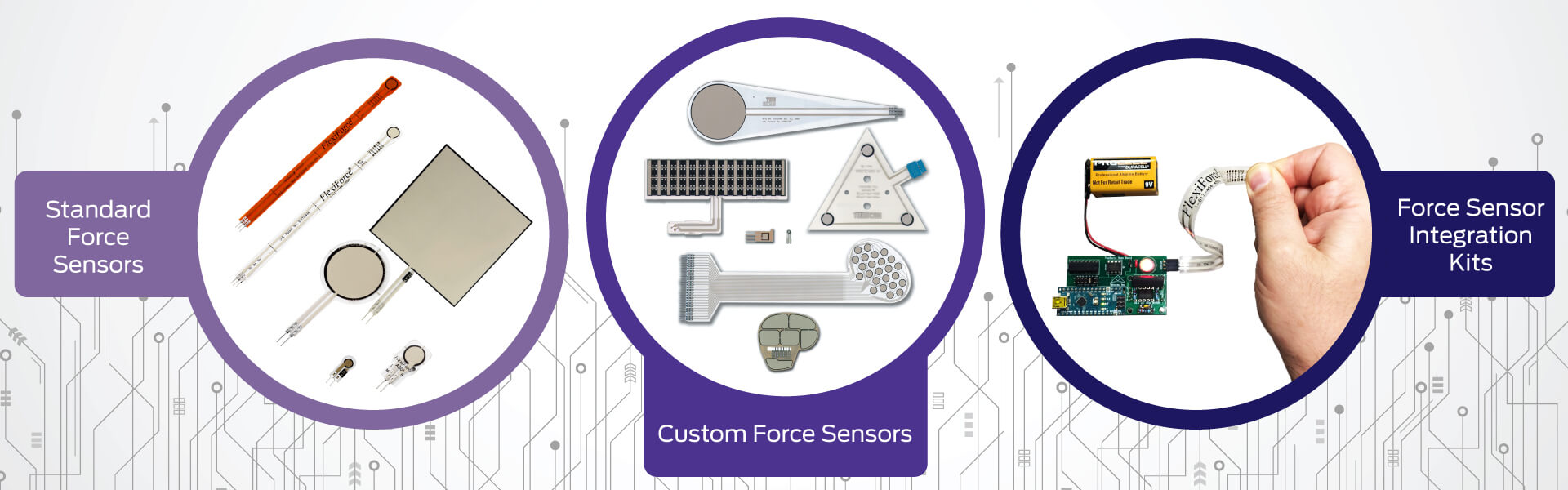

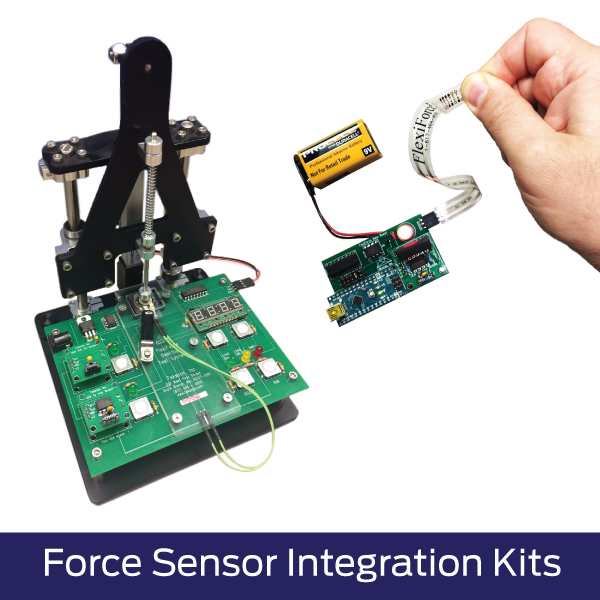

Embedded Force Sensors

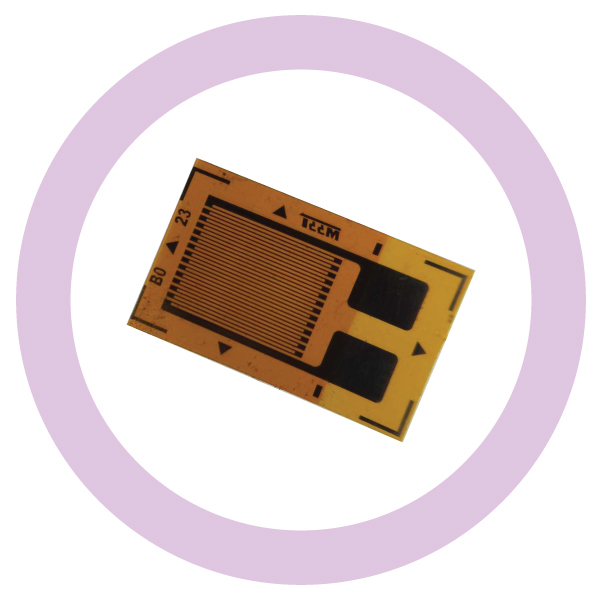

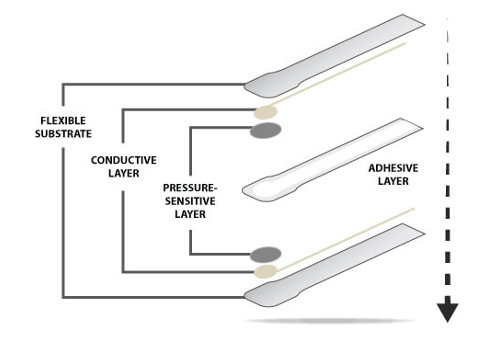

FlexiForce force sensors are ultra-thin and flexible printed circuits, which can be easily integrated into force measurement applications. FlexiForce sensors are available off-the-shelf, or can be customized for unique product designs.