Nip Pressure Alignment Tool

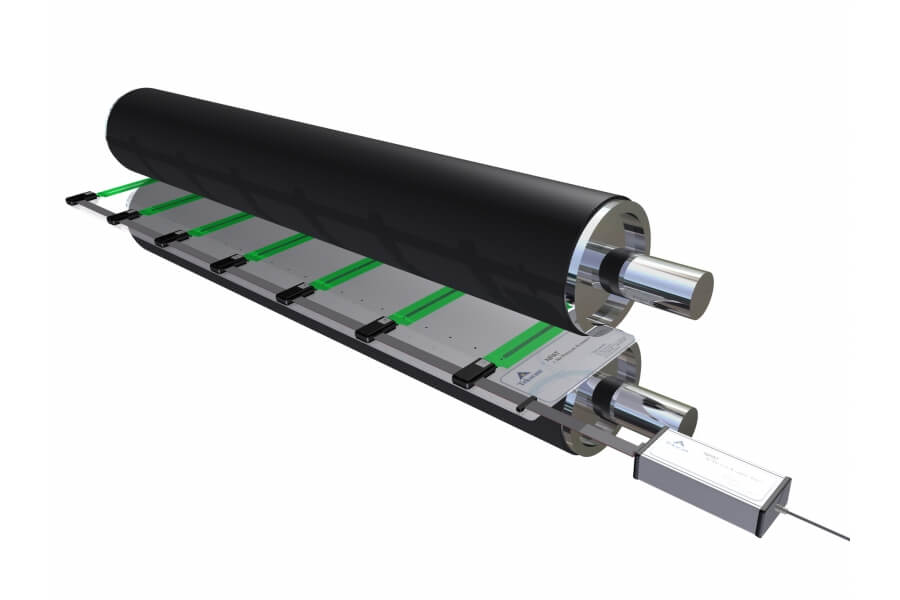

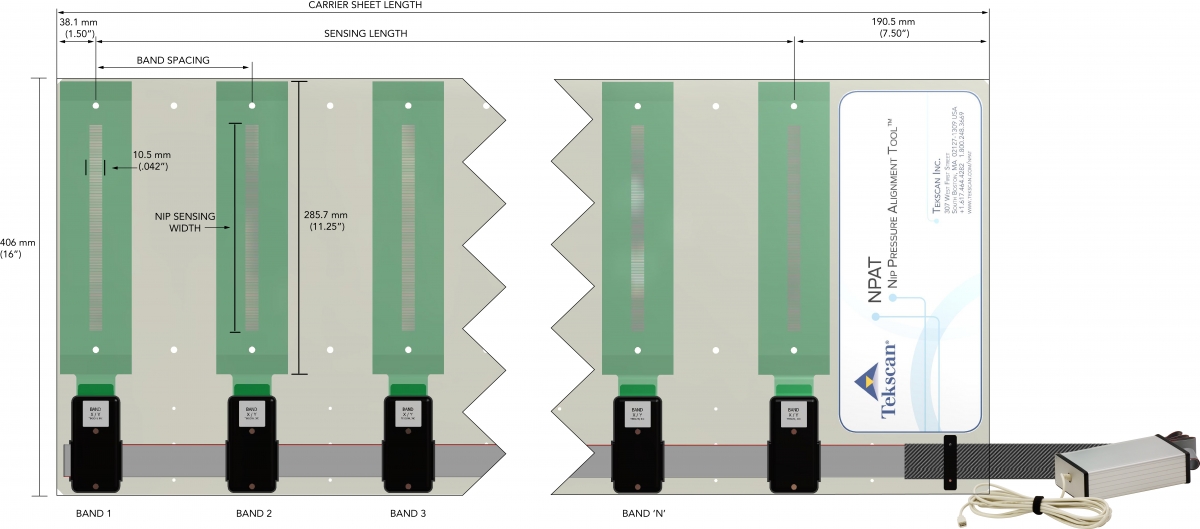

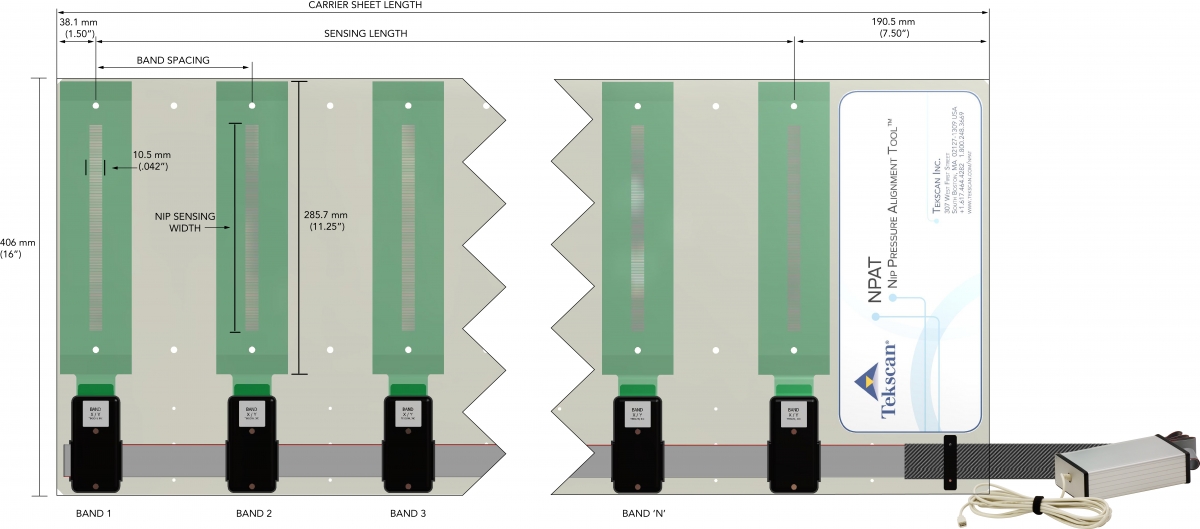

The NPAT is used to capture nip footprints and relative pressure distribution between nip rolls. The NPAT sensor band array can cover a very large area while utilizing one data acquisition handle.

Download Datasheet

Not available for online purchase.

Contact us for pricing

Nip Pressure Measurement

The Nip Pressure Alignment Tool™ (NPAT™) is a complete nip pressure and force measurement tool that takes the guesswork out of machine set-up. By using real-time data, the NPAT verifies uniform pressure and nip contact. The tool measures and displays, in real-time, nip widths between 6.35 mm (.25") and 215.9 mm (8.5").

|

Key Features:

- Configurable array of sensing bands

- Carrier to keep the bands/housing properly aligned during use

- Enclosure for the Evolution™ handle that protects electronics in more rugged applications

- Bands that can be easily replaced and serviced in-field

- Three sensor model resolutions to support different roll sizes

- Easily rolled up for storage

|

Benefits of Measuring Nip Pressure:

- Clear visual representation of pressure distribution, nip width, and cross width

- Ensures proper alignment

- Prevents equipment and product damage

- Provides quantifiable and credible data

- Easily maintained in-field

|

NPAT Helps Identify:

- Machine Comparison

- Preventative Maintanence

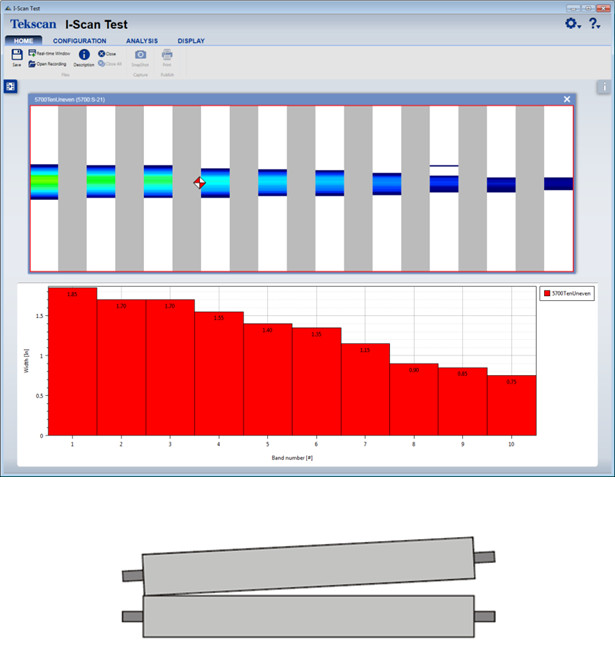

- Misalignment

|

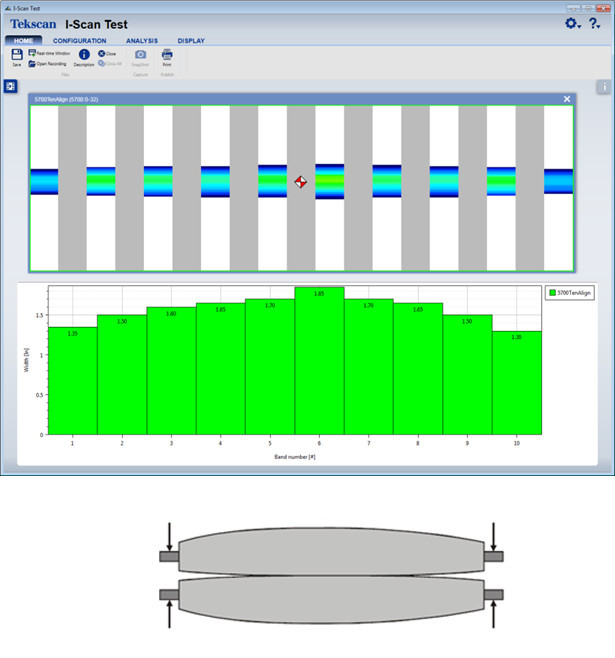

- Crowns

- Diameter Variations

- Deflections

|

NPAT Configurations

There are nine standard systems that each have their own spacing. All systems have a nip sensing width between 44.45 mm (1.75 in.) and 223.5 mm (8.80 in.). The system is able to measure pressures of up to 4,500 psi.

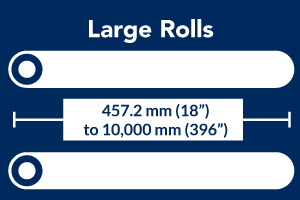

Select from Our Large and Small Roll Systems

Large Roll Configuration - NER5700 & NER5707

The 5700* and 5707** systems have one column per band. These systems are ideal for larger rolls in the printing industry.

* 5700 Sensing Band (1 column per band; MAX 13 bands/13 columns) is used to make sensors between 457.2 mm (18”) and 6,400.8 mm (252”).

** 5707 Sensing Band (1 column per band; MAX 17 bands/17 columns) is used to make sensors between 1,524 mm (60”) and 10,000 mm (396”).

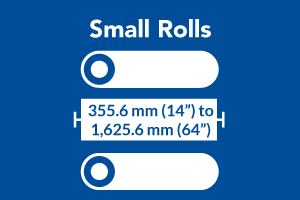

Small Roll Configuration - NER5705

The 5705*** system has 5 columns per band and the spacing of the columns is locked at 25.4 mm (1"). This system is ideal for smaller rolls in the film and converting industry.

*** 5705 Sensing Band (5 columns per band; MAX 13 bands /65 columns) is used to make sensors between 355.6 mm

(14”) and 1,625.6 mm (64”).

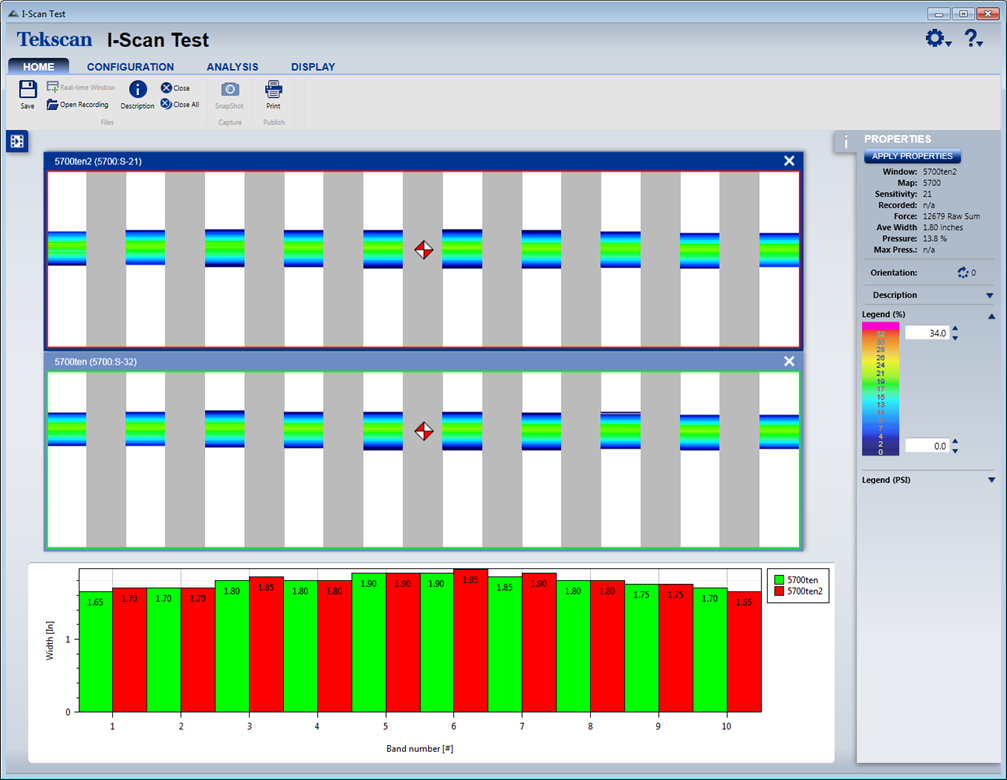

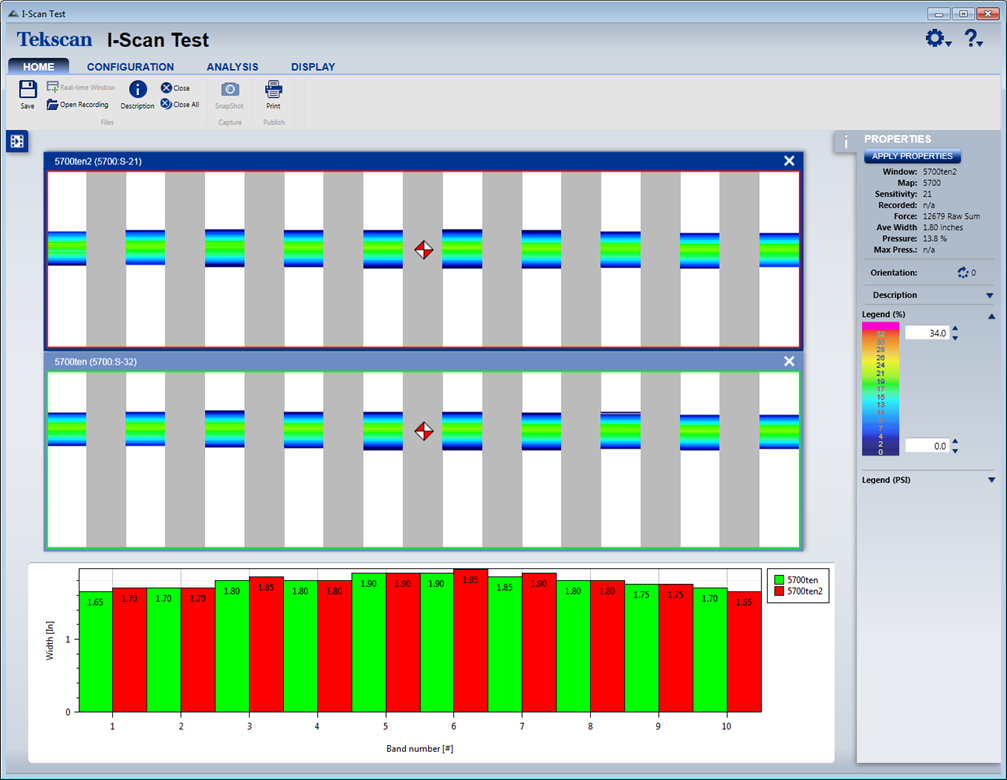

Software Features

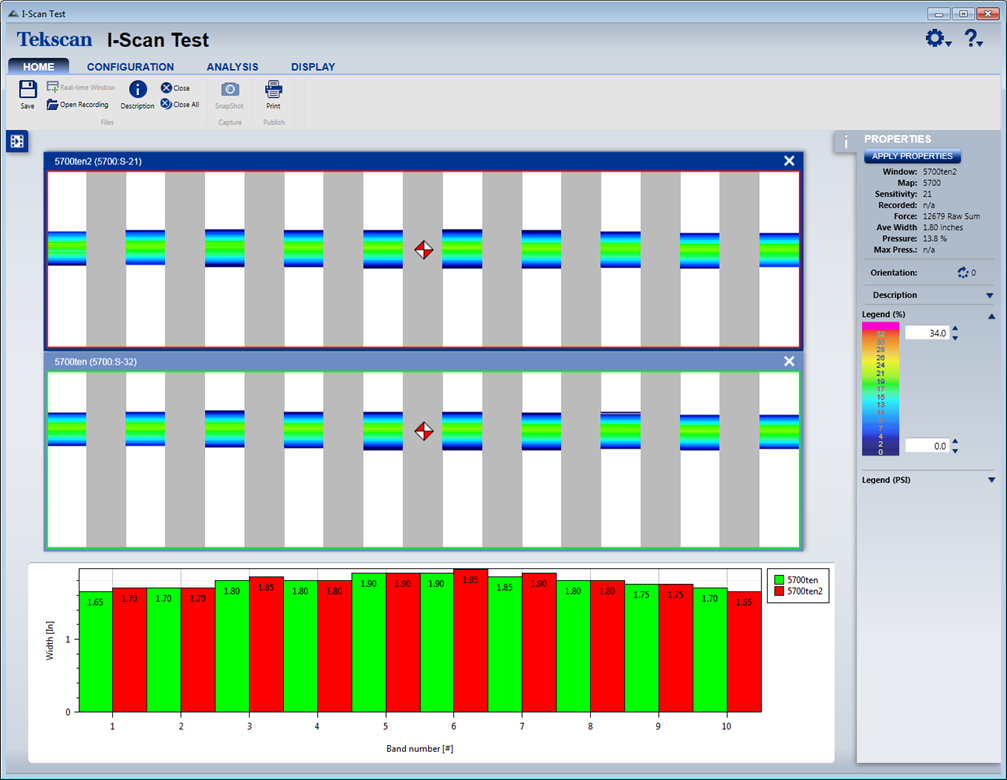

The software included has an easy-to-use interface that allows for fast and efficient machine set-up. It has a streamlined set of features that allows the user to easily identify nip uniformity. The pressure distribution across each band is displayed and can be saved as a snapshot of the image. More features include:

Compare previous reference snapshot

Compare previous reference snapshot

- Real-time display of pressure profile on bands across roll

- Graph Nip Width & Relative Force of each sensing band

- Center of force cursor verifies equal load from bearings

- Color scale of pressure values

- Compare real-time data with reference measurement previously taken

- Can be used with existing Evolution handle