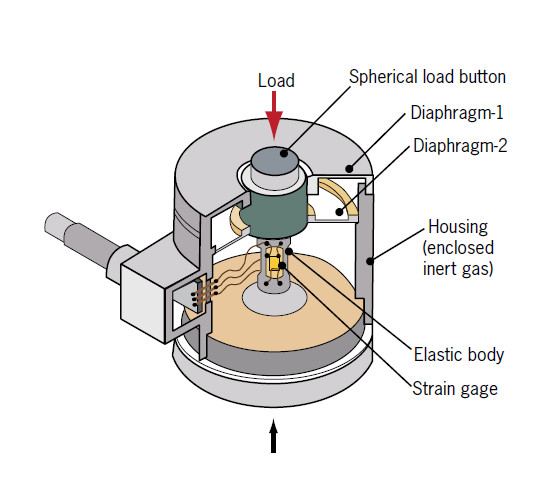

A load cell is a type of force sensor that, when connected to appropriate electronics, return a signal proportional to the mechanical force applied to the system. They can be hydraulic, pneumatic, or, most commonly, based on strain gauges.

|

|

Advantages of a Typical Load Cell

Disadvantages of a Typical Load Cell

|

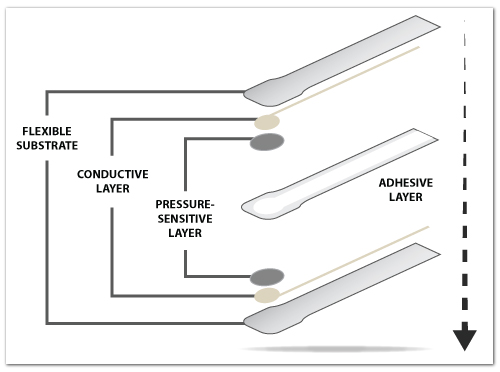

There are other types of force sensors available, such as force sensitive resistors (AKA, piezoresistive force sensors, or touch sensors) which measure force differently. A force sensitive resistor measures a compressive force directly instead of correlating the strain of a beam to force applied. The force applied to the sensor compresses two layers of a flexible, printed, piezoresistive ink together. This compression results in a proportional change in electrical signal, which like the signal of a load cell, can be calibrated to engineering force units.

|

|

Advantages of a Force Sensitive Resistor

Disadvantages of Piezoresistive Force Sensor

|

Does your product or application require force sensors?

Whether you are looking for an embedded sensor for an OEM application, or you need a force sensor for test and measurement purposes, there are a number of factors to consider in choosing the right technology. Our free whitepaper details the differences between the key technologies on the market..