Comparison of Thermal Surface Measurement Technologies

Temperature is one of the most common measurements in everyday life and is familiar to everyone. In scientific, industrial, and engineering fields, accurate measurement of surface temperature is essential for effective monitoring, diagnostics, and process control.

A variety of technologies have been developed to address the diverse requirements of thermal measurement, each offering unique advantages and limitations. Among these, Thermoscale, thermal cameras, thermocouples, and temperature mapping represent distinct approaches—ranging from qualitative visual indicators to high-resolution, real-time imaging and precise point measurements. Understanding the principles and capabilities of these methods is crucial for selecting the optimal solution for specific thermal analysis challenges.

Let's compare four thermal surface measurement technologies commonly used in engineering and industry: Thermocouples, Thermoscale film, Thermal Cameras, and Temperature Mapping.

Thermocouples

Thermocouples

1. Thermocouples

- Type: Contact-based, single-point measurement

- How it works: Two dissimilar metals generate a voltage proportional to temperature.

-

Pros:

- Inexpensive and widely used

- Simple and rugged

- Wide temperature range

-

Cons:

- Only measures at a single point, complex to use for multiple points

- Requires wiring and data acquisition

- Can be intrusive

- Best applications: Industrial processes, point temperature measurements in engines

More info on Thermocouples.

Thermoscale Film

Thermoscale Film

2. Thermoscale Film

- Type: Contact-based, visual indicator film

- How it works: A heat-sensitive film changes color based on surface temperature.

-

Pros:

- Simple and low-cost

- Good for identifying hot spots and heat distribution

- No power required

-

Cons:

- Single-use or limited reuse

- No real-time data

- Not quantitative (color change is approximate)

- Best applications: Quick diagnostics in electronics, motors, or heat sinks

More info on ThermoScale from Fujifilm.

Thermal Camera

Thermal Camera

3. Thermal Cameras (Infrared Thermography)

- Type: Non-contact, optical

- How it works: Detects infrared radiation and converts it into a thermal image showing surface temperature.

-

Pros:

- Real-time imaging

- Suitable for ambient or harsh environments

- High spatial resolution

-

Cons:

- Expensive

- Requires calibration and training

- Affected by emissivity and environmental conditions

- Best applications: Industrial and electrical inspections, preventative maintenance, thermal vacuum testing

Temperature Mapping

Temperature Mapping

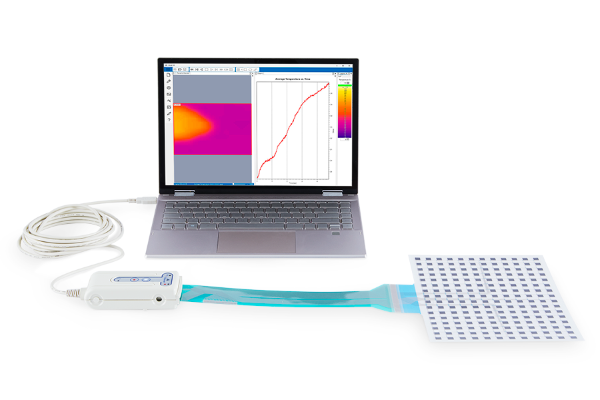

4. Temperature Mapping

- Type: High-resolution 2D temperature distribution with real-time monitoring.

- How it works: Uses an array of thin-film sensors to map temperature across a surface to create a detailed temperature map

-

Pros:

- Detailed spatial temperature distribution

- Provides continuous monitoring

- Compare and track data in software for validation and compliance

-

Cons:

- Requires placement on surface

- Potentially less robust than thermocouples

- Requires data processing and external hardware

- Best applications: Product design, material testing, process control

More info on Temperature Mapping.

Summary Table

| Temperature Mapping | Thermoscale | Thermal Camera | Thermocouple | |

|---|---|---|---|---|

| Output | Detailed temperature maps | Color change indicator | Thermal images | Single point temperature values |

| Contact | Contact | Contact | Non-contact | Contact |

| Spatial Resolution | High Trimmable Sensor |

Medium | High | Single Point |

| Quantitative capability | Yes, on all material types with built in graphing capability | No | Yes (dependent on material emissivity) | Yes |

| Dynamic/Static | Dynamic across a surface | Static | Dynamic | Dynamic at a single point |