Beyond the Battery Pack - How Temperature Mapping Can Be Used Across the Electric Vehicle

This post is part of our ongoing series on spatial pressure and temperature mapping in electric vehicles. While earlier posts focus on battery packs, here we take a broader view across the vehicle.

Battery packs dominate most conversations around spatial pressure and temperature mapping — and for good reason. But they are only one part of the thermal and mechanical equation in an electric vehicle. Across the EV, OEMs and tier one suppliers face tightly coupled heat, load, and integration challenges in power electronics, motors, thermal systems, charging hardware, and structural interfaces.

The same measurement principles used to understand battery behavior can be applied far beyond the pack perimeter. At Tekscan, we’ve designed our integrated pressure + temperature mapping platform with flexibility in mind, enabling engineers to apply spatial measurement wherever mechanical loading and thermal performance intersect.

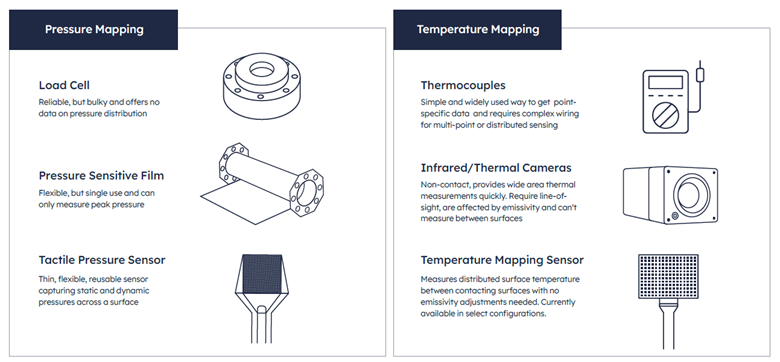

Throughout this post, “spatial pressure and temperature mapping” refers to measuring how pressure and heat are distributed across a surface — not just at a single point — and how those patterns evolve over time. This approach enables correlation between mechanical contact, thermal behavior, and system performance in ways point sensors cannot.

Use-case areas across the EV

Below are several EV subsystems where spatial pressure and temperature mapping provides insight that’s difficult to obtain with traditional measurement approaches.

Power electronics (inverter, converter, charger)

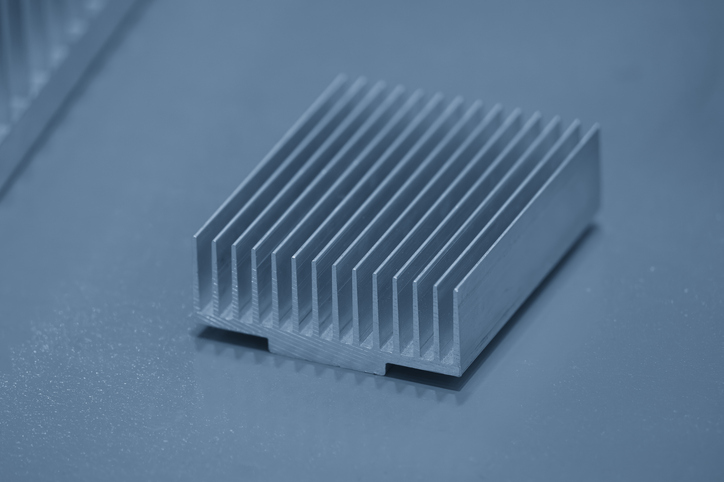

Thermal hotspots and uneven clamping forces are common reliability drivers in high-current switching assemblies. These devices contain internal busbars, heat sinks, and tightly constrained mechanical stacks. Spatial temperature mapping highlights gradients across heat sinks and cooling paths, while pressure arrays reveal contact force variation between modules, busbars, or clamped interfaces — helping engineers identify cooling inefficiencies, stress concentrations, and potential failure points.

Thermal hotspots and uneven clamping forces are common reliability drivers in high-current switching assemblies. These devices contain internal busbars, heat sinks, and tightly constrained mechanical stacks. Spatial temperature mapping highlights gradients across heat sinks and cooling paths, while pressure arrays reveal contact force variation between modules, busbars, or clamped interfaces — helping engineers identify cooling inefficiencies, stress concentrations, and potential failure points.

Electric motor & gearbox interface

The interface between the stator, bearings, gearbox housing, and cooling structures relies on subtle mechanical tolerances and effective thermal pathways. Mapping pressure at housing–stator interfaces, alongside temperature distribution across the motor casing or cooling jacket, helps detect early signs of misalignment, bearing preload imbalance, or localized cooling inefficiencies before they escalate into durability issues.

Thermal management systems (cooling plates, coolant header blocks, heat exchangers)

Effective heat removal depends not only on coolant flow but also on consistent mechanical contact. Spatial temperature mapping reveals flow irregularities and thermal gradients within cooling plates or manifolds, while pressure mapping confirms uniform clamping between plates and adjacent components. Together, these measurements help engineers optimize heat transfer performance and validate assembly consistency.

Charging and power-connection hardware

High-power charging introduces large currents, tight mechanical interfaces, and localized heating risk. Spatial temperature mapping across connector and contact interfaces helps identify emerging hotspots, while pressure mapping monitors clamp force or contact pressure within busbar and connector assemblies — supporting safer, more reliable power delivery designs.

Chassis and structural battery-pack integration

As battery modules become structural elements of the vehicle, the mechanical coupling between the pack enclosure and vehicle frame directly affects both thermal performance and structural integrity. Mapping pressure at these interfaces — and the resulting temperature distribution across enclosures or structural members — helps optimize integration strategies for load sharing, cooling effectiveness, and long-term durability.

As battery modules become structural elements of the vehicle, the mechanical coupling between the pack enclosure and vehicle frame directly affects both thermal performance and structural integrity. Mapping pressure at these interfaces — and the resulting temperature distribution across enclosures or structural members — helps optimize integration strategies for load sharing, cooling effectiveness, and long-term durability.

Why this matters for manufacturing and reliability

Across these applications, the underlying challenge is the same: performance and reliability depend on how evenly heat and mechanical load are distributed, not just their peak values.

By applying spatial pressure + temperature mapping across EV subsystems, teams gain:

- Design validation insight - Visualize where mechanical and thermal loads concentrate before full production, enabling informed design iteration.

- Manufacturing quality assurance - Establish pressure and temperature baselines during assembly and detect deviations that may indicate process drift.

- Reliability monitoring - Repeated mapping during durability or accelerated life testing reveals early signs of mechanical degradation or thermal drift.

- Cross-discipline optimization - Because mechanical contact and thermal behavior are tightly linked, spatial mapping supports informed trade-off decisions — for example, balancing clamp pressure for thermal conduction versus mechanical stability.

How Tekscan supports this breadth of applications

Our mapping platform is modular by design. The same sensor arrays and hardware architecture used for battery-pack validation can be applied to other EV subsystems — from cooling plates and motor housings to connector assemblies and structural interfaces.

We support custom-form pressure arrays, flexible film sensors, temperature overlays, and software capable of handling multiple geometries and subsystem types. Our applications team collaborates with customers to identify key measurement zones, define baseline maps, and build data workflows that support design validation, manufacturing quality, and reliability analysis.

Extending Spatial Mapping Beyond the Battery Pack

Across the electric vehicle, critical subsystems depend on the interaction between mechanical load and thermal behavior — and spatial mapping makes those interactions visible.

Whether you’re targeting improved cooling performance, more robust motor assemblies, safer charging hardware, or better structural integration, spatial pressure + temperature mapping from Tekscan provides actionable data to support development and manufacturing decisions.

Contact us to explore how spatial mapping can be applied to your next EV subsystem.