Optimizing the Temperature Sensor Calibration Process in Pressure-Temperature Mapping

Calibration matters: getting your temperature map right unlocks the full value of the system.

Accurate temperature mapping depends on more than sensor resolution—it depends on calibration. In systems that measure pressure and temperature simultaneously, even small temperature offsets can influence how contact mechanics, heat transfer, or process stability are interpreted. Without proper calibration, spatial temperature data may be repeatable, but not necessarily accurate or actionable.

Temperature calibration anchors sensor output to known reference points, ensuring that measured temperature distributions reflect true physical conditions across the sensing area. Whether used in R&D, validation testing, or manufacturing environments, a well-defined calibration process is essential for maintaining confidence in pressure + temperature mapping results over time.

Why Calibration is More than “Just a Thermostat Check”

While thermocouples are commonly used as independent temperature references, calibrating a spatial temperature array involves more than verifying a single point measurement. In pressure + temperature mapping applications, accuracy must be maintained across the entire sensing area—not just at one location.

Temperature calibration in a spatial array is more complex than a single thermocouple check because:

- Multiple sensing elements are involved. You have many individual sensing elements (pixels) across a map; each may have slight offset or gain error that must be accounted for.

- Temperature gradients matter. The temperature field across a battery cell or module is rarely uniform. How baseline or “zero” conditions are defined directly affects how gradients and localized hot spots are interpreted.

- Mechanical interaction can influence readings. Compression, fixture constraints, and thermal expansion, especially when pressure sensors are involved, can shift temperature sensor response and must be considered during calibration.

- Environmental factors introduce spatial bias. Cooling plates, airflow, adjacent cells, or surrounding structures can influence temperature distribution in non-uniform ways across the sensing area.

- Automated measurements require traceability. In manufacturing and validation environments, calibrated temperature data must be comparable across multiple units, systems, and time points, often with traceable documentation.

Recommended Calibration Workflow

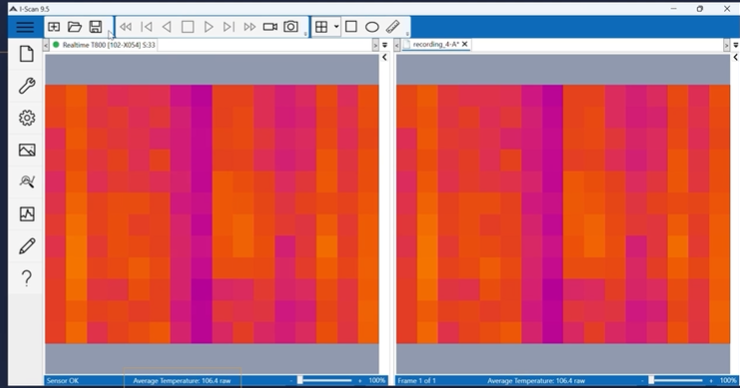

Calibration Reference PointsThe following step-by-step calibration protocol outlines Tekscan’s recommend approach for calibrating the I-Scan Temperature Mapping Solution.

Calibration Reference PointsThe following step-by-step calibration protocol outlines Tekscan’s recommend approach for calibrating the I-Scan Temperature Mapping Solution.

- Stabilize the temperature reference. Allow the device generating the known temperature (e.g., hot plate or thermal chamber) to reach thermal equilibrium.

- Position the temperature sensor. Place the temperature sensor in full contact with the surface under test, ensuring consistent contact across the sensing area.

- Capture uncalibrated reference frames. Take three uncalibrated snapshots at known temperatures to establish calibration reference points

- Create a calibration movie. Merge the calibration files into a three-frame movie using Tekscan software.

- Apply frame calibration. Perform frame calibration by assigning the known temperature values to each reference frame.

View the video for complete, step by steps calibration instructions.

How Tekscan Supports You

Tekscan provides calibration software modules, guidance documentation, and optional on-site calibration support from our engineering team. We help you define the calibration tolerances that suit your manufacturing or validation environment (for example, ±0.3 °C baseline, ±0.5 °C span uniformity) and establish workflows (SOPs) aligned with your measurement process.

Calibration data is fully integrated into the Tekscan software environment, enabling users to:

- Overlay pre- and post-calibration temperature maps

- Track temperature drift over time

- Trigger alerts when recalibration thresholds are exceeded

This integrated approach helps ensure temperature data remains accurate, traceable, and aligned with quality or validation requirements.

Build the Foundation for Reliable Insight

Proper temperature calibration is not optional; it is foundational to extracting reliable, meaningful insights from pressure and temperature spatial mapping. Whether you are deploying the Tekscan solution in an R&D lab or a production environment, Tekscan can help you define calibration thresholds, establish repeatable workflows, and maintain confidence in your measurement data from day one.

Contact our team to explore pressure + temperature mapping or to review your calibration approach for long-term accuracy across your application.