Controlling the Costs of Renewable or Recyclable Food Packaging with Pressure Mapping Technology

Cardboard and paper board products, like these, are excellent biodegradable options for containing food products. However, they may present challenges in your packaging processes.It seems like every week there’s another news headline announcing a different food & restaurant company taking an initiative to reduce the use of non-renewable packaging materials in their operations – especially plastic. While some companies have transitioned to more environmentally-responsible product packaging on their own, many operations in Europe are under political pressure to make the switch, after the EU adopted an aggressive mandate earlier this year to make all packaging recyclable by 2030.

Cardboard and paper board products, like these, are excellent biodegradable options for containing food products. However, they may present challenges in your packaging processes.It seems like every week there’s another news headline announcing a different food & restaurant company taking an initiative to reduce the use of non-renewable packaging materials in their operations – especially plastic. While some companies have transitioned to more environmentally-responsible product packaging on their own, many operations in Europe are under political pressure to make the switch, after the EU adopted an aggressive mandate earlier this year to make all packaging recyclable by 2030.

Despite their environmental benefits, the higher up-front costs for using product packaging composed of recycled or renewable materials is the most significant hurdle for many food-processing or packaging companies. Some of the more common alternatives for plastic packaging include:

- Synthetic, biodegradable polyester materials

- Milk proteins

- Woven materials like canvas or cotton

- Paperboard

-

Glass

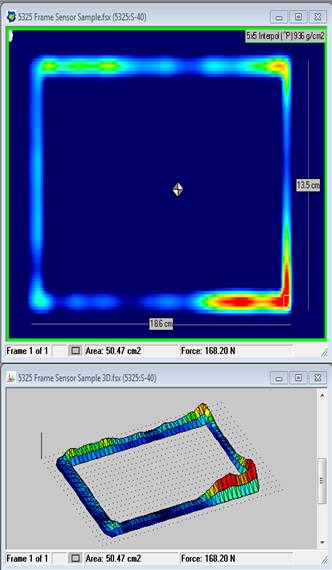

Example of a pressure mapping application for evaluating an even the seal on a food container, similar to the biodegradable container pictured above.Along with their varying price-points, some of these materials also come with durability or flexibility concerns, depending on the type of food products they contain. These materials can be softer, harder, and have generally different characteristics than the materials the packaging machines are designed to produce, which must be considered during machine setup.

Example of a pressure mapping application for evaluating an even the seal on a food container, similar to the biodegradable container pictured above.Along with their varying price-points, some of these materials also come with durability or flexibility concerns, depending on the type of food products they contain. These materials can be softer, harder, and have generally different characteristics than the materials the packaging machines are designed to produce, which must be considered during machine setup.

Any material loss from a faulty packaging production run costs company revenue, no matter what type of material they are using. However, those costs are compounded when considering the high prices for using recyclable source materials. Also, even if the packaging is produced and assembled to specifications, there is significantly more damage and loss risks involved when shipping packaging that incorporates renewable or recyclable materials.

One way these companies can get the full return on their investment is by employing smart manufacturing technology that helps operators:

- Better understand their assembly process

- Select the right materials types for the contained product

- Ensure a safe and reliable delivery to the consumer

Gain Greater Insight on Your Packaging Process with Pressure Mapping Technology

Whether used in machine design R&D, an on-the-floor maintenance tool, or an embedded feature within the machine interface, pressure mapping technology is a useful tool that delivers ROI-driving insights on machine setup and alignment. This information takes the guessing-game out of machine setup, which pays dividends when working with recyclable packaging materials. Some applications include:

- Packaging Machine Sealing Jaw Pressures

- Packaging Design and Manufacturing Assessment

- Nip Roll Uniformity & Pressure Distribution

This eBook shares how all of the different ways pressure mapping technology can be used in all facets of machine alignment, including real-world examples for packaging applications.

Moreover, pressure mapping can be useful in evaluating the sturdiness of a packaging design. This includes applications for understanding how a recycled packaging design will withstand drops or impacts, or to determine how to safely stack or ship these packaged goods, pressure mapping technology helps ensure food makes it safe and secure to its destination.

Going green with recyclable or renewable packaging comes with risks, but those risks can be mediated with greater insight into the infinite details of the entire packaging process from assembly, through delivery.

For more answers to your printing & packaging questions, contact one of our industrial sales engineers today.