Accidents Happen - Pressure Mapping Can Help R&D Teams Mediate Their Effects

Durability can be an important differentiator for many types of products. When choosing between two similar products, customers may prefer the option that is created with rugged components and sturdy materials that ensure a robust design. Research & development (R&D) teams of all kinds invest lots of time and money into testing how their product will withstand the effects of high-speed impacts, such as when a product is accidentally dropped or collides with another surface. Pressure mapping technology can be a useful test & measurement technology to help R&D teams improve their product designs to be more resilient when accidents happen.

For product packaging, it's what's on the outside that counts

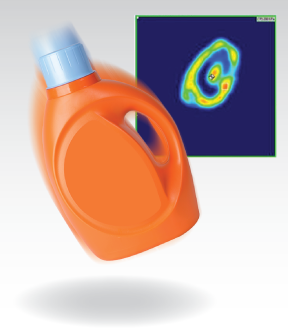

One example of how product durability can influence a buyer's purchase decision is in the household cleaning product market. Take laundry detergent for instance: There are several different brands of laundry detergents on the market, many of which mention similar features and benefits on their product labels. Therefore, customers may rely on other comparative features - such as the quality of product packaging - to help make their decision.

In a recent drop testing experiment, a laundry detergent company used pressure mapping technology to test the durability of their new product packaging design. They dropped the container from various heights, angles and speeds onto a low resolution sensor that measured at 20 KHz to identify concentration of pressure. With this pressure data, the R&D team was able to ensure the bottom of the container could handle repeated drops without any breaks or leaks.

Achieve greater product durability while keeping end users safe

![CC BY 2.0 (http://creativecommons.org/licenses/by/2.0)], via Wikimedia Commons](/sites/default/files/Razer_OSVR_Open-Source_Virtual_Reality_for_Gaming_%2816863422875%29.jpg) CC BY 2.0 (http://creativecommons.org/licenses/by/2.0)], via Wikimedia Commons

CC BY 2.0 (http://creativecommons.org/licenses/by/2.0)], via Wikimedia Commons

Pressure mapping technology was recently used in an impact testing experiment which evaluated the sturdiness of virtual reality (VR) goggle designs. In this unique application, tactile pressure sensors were strategically placed around the edges of the VR goggles, which were collided with surfaces at various impact forces to determine the product's durability.

Considering the fact that users wearing the VR goggles are less likely to be aware of their real-world surroundings, the pressure data captured from this experiment could help play a major role in both improving the VR goggle's design and keeping end users safe. This data could also be used to help the company develop the terms for their user warranty, which could become a significant competitive differentiator against similar products.

Invest in technology to protect your customer's investment

Let's face it; you may never be able to protect your product from 100% of all mishaps. However, pressure mapping technology can help provide critical data to help design a product that your customers can be confident will withstand the rigors of everyday use. Making the effort to address product durability now will help protect against product recalls or other quality issues.

You only have one chance to win over your customers after a product heads to market - pressure mapping technology helps ensure product designs will meet their expectations for durability.

Previous Post: | Next Post: |