Designing the Superior Flying Experience Challenge: Above all other methods of public transit, commercial airlines face the most scrutiny for the measures they take to provide passengers with a comfortable experience. Designing a one-size-fits-all seat that addresses the comfort needs of a global...

Applications

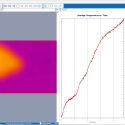

Pressure, Force and Temperature Measurement Applications

Tekscan's force, pressure, and temperature sensors and measurement systems are used in a wide variety of OEM, Research and Development, and Clinical applications. If you don't see your application listed below, contact us to discuss the opportunity.

Displaying 1 - 10 of 67