Automotive Interior Impact Testing

How does an engineer at a major automaker validate the safety of an electric vehicle’s interior with confidence?

When an engineer responsible for interior physical testing validation for an electric vehicle model at a major automaker wanted to confirm the safety of the car interior, he turned to Tekscan.

What were the results?

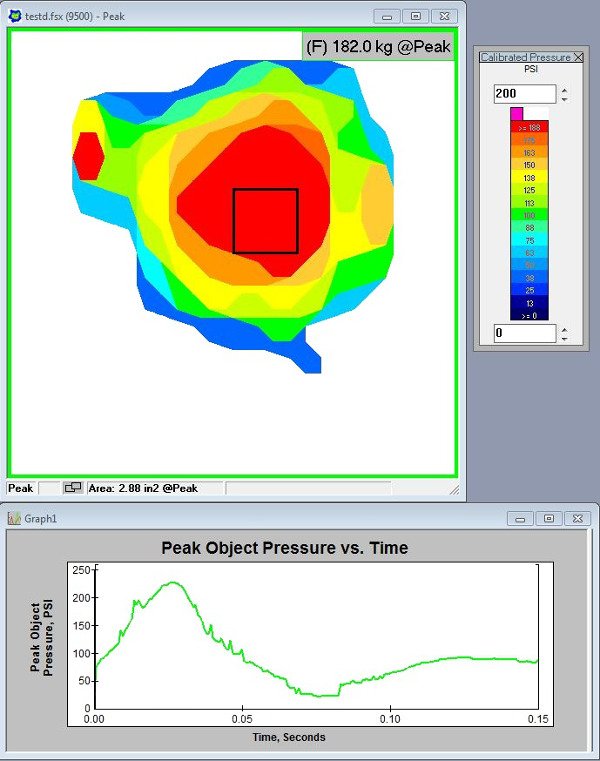

The high speed I-Scan™ force and pressure mapping system was purchased to study dynamic pressure and impact force during an impact. I-Scan can identify the temporal, local, peak, and spatial pressures at the collision point. You can use the data our system can provide to validate finite element analysis (FEA) computer models that predict the forces and pressures on the various surfaces within the passenger compartment.

The large footprint of the 5315-A sensor combined with high-speed electronics capable of scanning speeds of 20,000 Hz was the perfect solution.

New automotive engineering designs for EVs in particular produce very different impact dynamics. This impact peak force and pressure distribution information can be used to create safer cars for dashboard, headrest, and seatbelt design, and measure airbag deployment to minimize injury. Sensors are available in different shapes to conform around curved surfaces, consoles, and seating. They are reusable and provide accurate pressure readings.

Get our new eBook to see how to Improve Automotive Design with Pressure & Temperature Mapping

Tekscan’s surface sensing solutions — now including temperature mapping — provide deeper visibility into what happens between two contacting surfaces.

By capturing real-time pressure and temperature distribution, engineers gain critical data to:

- Validate structural integrity

- Ensure proper sealing and fit

- Optimize manufacturing processes

- Reduce costs and improve consistency