Engineering a Stable Battery Housing

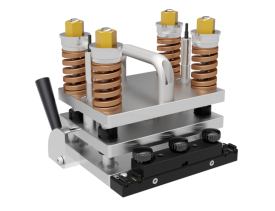

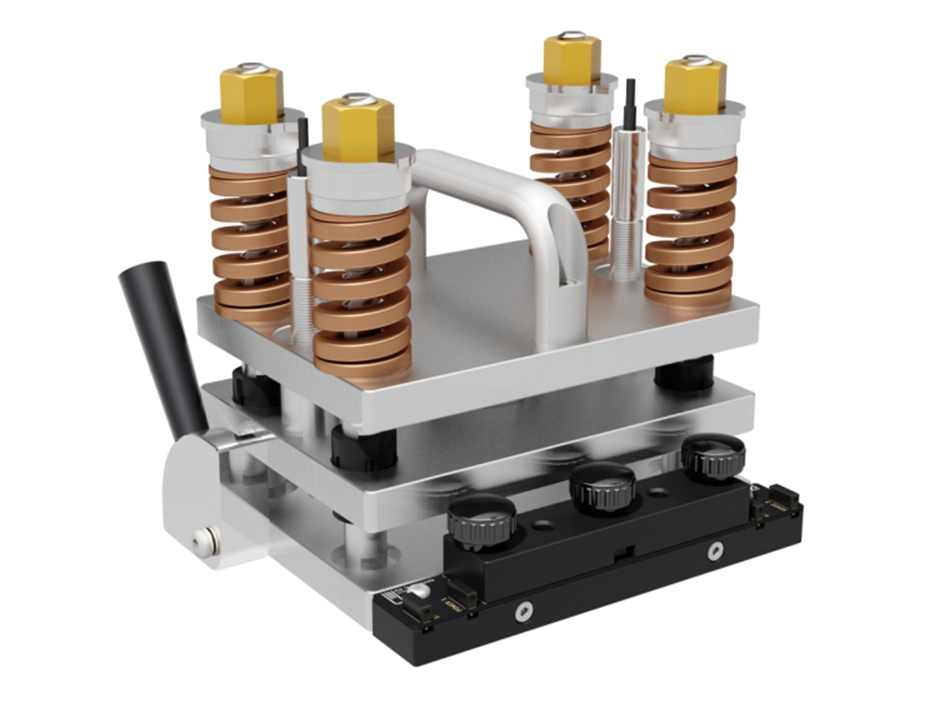

The team used a precision clamping fixture

to apply consistent force during cycling

The team used a precision clamping fixture

to apply consistent force during cycling

Challenge

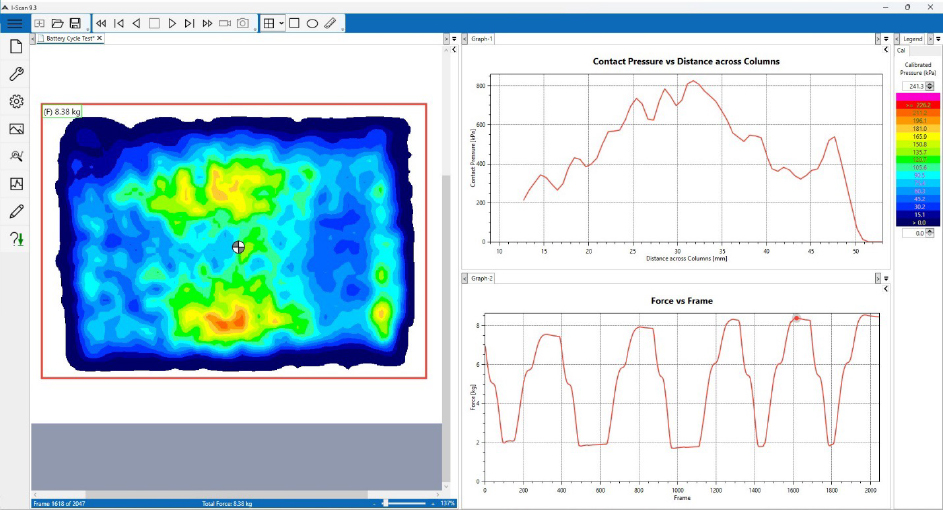

During early module testing, a battery manufacturer observed localized housing deformation and edge-seal failures after repeated charge/discharge cycles. Post test inspections revealed subtle swelling and misalignment in the cell stack—but the root cause wasn’t clear. Conventional load cells captured total force, indicating that deformations in the housing were occurring, but provided no insight into where exactly pressure was accumulating across the housing.

Solution

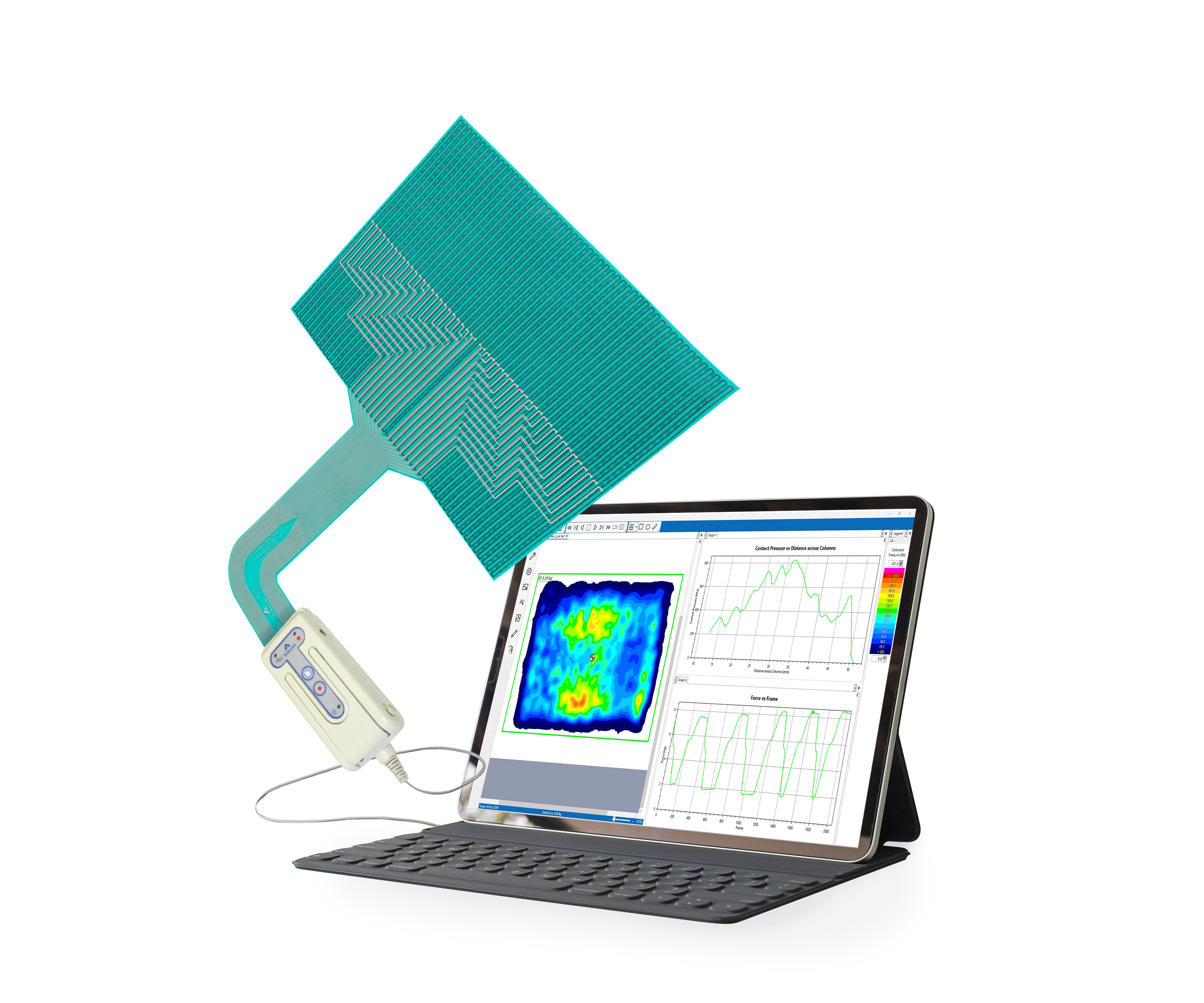

To create a controlled and repeatable compression environment, engineers used a precision clamping fixture (e.g., RHD’s ComprePouch) to apply consistent force during cycling. Tekscan’s I-Scan thin-film pressure sensors were then embedded between the cell stack and housing to capture spatial pressure maps throughout the cycling test. This made it possible to see exactly where pressure built up along certain edges, monitor how the load distribution shifted as the cells expanded, and compare different housing and clamping designs under identical conditions.

Key Insights & Actions

- I-Scan Software pinpointed edge stress concentrations causing housing distortion.

- The team adjusted the clamping strategy and wall thickness to equalize pressure along the

perimeter. - Verified uniform stack compression over extended cycling

- Insights shortened design iterations from weeks to days

- The team delivered a stiffer, more durable housing that supports tighter tolerances and longer cell life

Result: More Robust, Predictable, and Scalable Housing Design

By combining a controlled compression fixture with real-time pressure visualization, the team moved from trial-and-error experimentation to measurable, repeatable mechanical validation. This approach gave the team a clear window into

how their battery housing behaves under real operating conditions.

Teskcan's spatial pressure and temperature mapping system, along with a stable test figure housing, helps engineers understand when battery cycle pressure changes normal, and when they reveal a defect or design flaw.