High Speed TireScan

Capture & Analyze Tire Behavior at Speeds Up to 265 km/h (165 mph).

Not available for online purchase.

Contact us for pricing

Have questions? Contact Us

Capture & Analyze Tire Behavior at Speeds Up to 265 km/h (165 mph).

Not available for online purchase.

Contact us for pricing

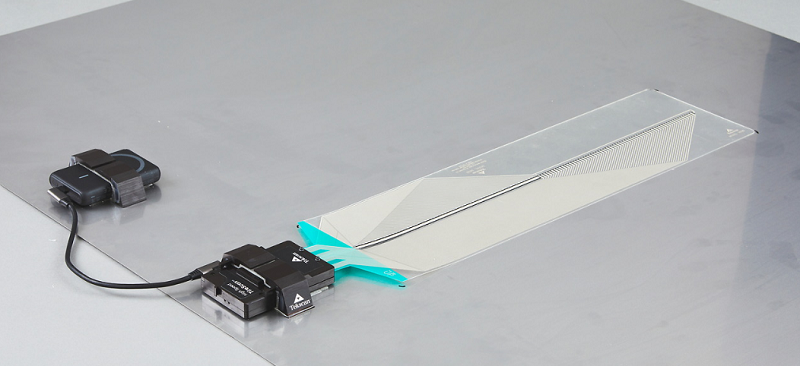

Tekscan’s High Speed TireScan™ system captures the impact of speed, motion, and inertial forces on a tire at speeds up to 265 km/h (165 mph). The robust array of pressure sensing elements scans at 20 kHz as the tire rolls across it. The software displays the tire shape and pressure distribution while in motion. The software displays the tire patch and pressure distribution while in motion.

|

Key Features & Benefits:

Key Applications:

|

|

|

The thin sensor is durable and robust enough to handle the aggressive conditions of tire testing. For example, the sensor can:

|

|

|

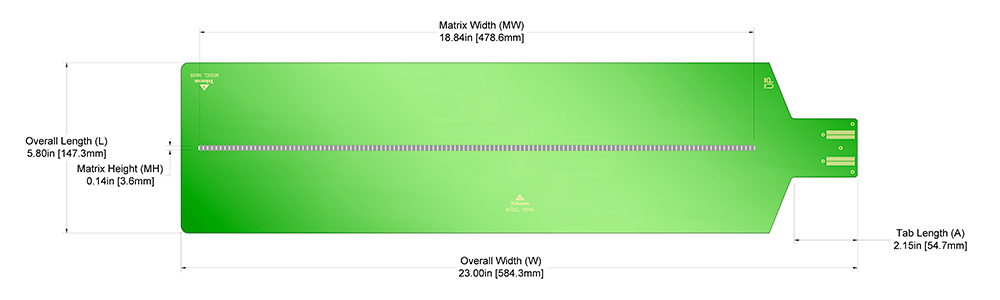

9606Sensor ConfigurationThis larger sensor is ideal for the following types of tires:

|

|

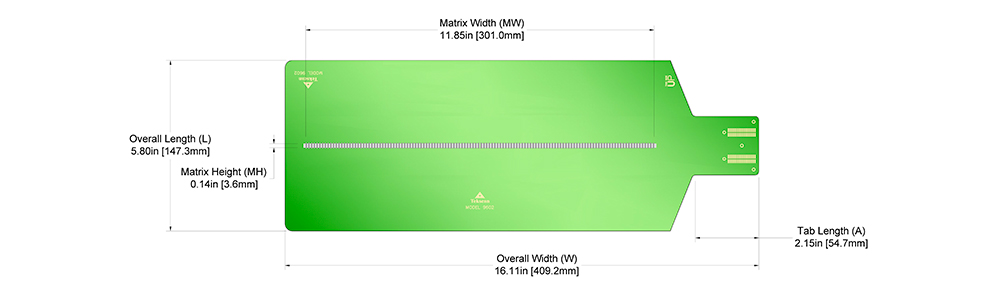

9602Sensor ConfigurationThis smaller sensor is idea for the following types of tires:

|

|

TekDAQ 210

|

|

The High Speed TireScan software module provides the tools for a more comprehensive and higher quality analysis. The software displays the pressure distribution data in multiple formats. The user has the option to create and customize reports from the corresponding tire data and export as a CSV or Microsoft Word file format.

Software AnalysisHigh-Speed TireScan™ software is designed to streamline the data collection process for efficient analysis |

Tire Geometry RecognitionHigh Speed TireScanTM captures key tire shape changes that can occur from centrifugal forces at different speeds. This example shows how one tire design was affected when tested at 48 km/h (30 mph), and again at 193 km/h (120 mph). |

Get the Tekscan’s High Speed TireScan system detailed Tire Testing EBook/White Paper.

Watch this webinar to learn how product design, manufacturing, research and quality control in the automotive industry can be improved by utilizing interface pressure measurement.

Take the Lead in Performance, Safety, and Comfort with Interface Pressure Measurement

Pressure mapping technology plays a critical and expanding role in battery formation for optimizing performance, maintaining quality, ensuring safety, and advancing battery technology through research and development efforts.