How Does a Force Sensing Resistor (FSR) Work?

Printed, thin, and flexible sensors have caused quite the buzz around the design engineering community in recent years. This is due largely to the boom of smart, lightweight, and power-efficient technologies, which have become entrenched in our everyday lives. Naturally, when designing these compact but powerful devices and products, the embedded components that make them game-changing innovations should also share those same traits.

Force sensing resistors (AKA, printed force sensors, or force sensitive resistors) are a large and growing group of embedded components, with many new sensor types having been introduced in recent years. However, force sensing resistors are not a new technology at all. In fact, force sensing resistors have been used as an embedded component for decades.

This article shares the basics of force sensing resistor technology, how they work, and how they can be used to capture force measurements as an embedded component within a device.

How do Force Sensing Resistors Measure Force?

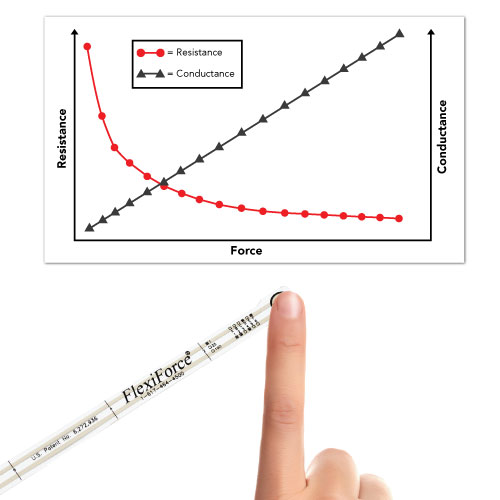

Figure 1: When force is applied to a force sensing resistor, the conductance response as a function of force is linear.Most engineers have learned that the formula for force is an object’s mass multiplied by its acceleration (or, F=M*A), or, applied pressure multiplied by the contact area (F=P*Area). There are several engineering units to represent “F” in these equations, such as Newtons (N), pound-force (lbf), and others.

Figure 1: When force is applied to a force sensing resistor, the conductance response as a function of force is linear.Most engineers have learned that the formula for force is an object’s mass multiplied by its acceleration (or, F=M*A), or, applied pressure multiplied by the contact area (F=P*Area). There are several engineering units to represent “F” in these equations, such as Newtons (N), pound-force (lbf), and others.

On their own, force sensing resistors are not pre-calibrated to correlate a force reading to a known engineering unit. However, the force measurement output captured by a force sensing resistor can be correlated to the applied force through a calibration procedure.

Force sensing resistors are a piezoresistive sensing technology. This means they are passive elements that function as a variable resistor in an electrical circuit. As shown in Figure 1, when unloaded, the sensor has a high resistance (on the order of Megaohms (MΩ)) that drops as force is applied (usually on the order of Kiloohms (KΩ)). When you consider the inverse of resistance (conductance), the conductance response as a function of force is linear within the sensor’s designated force range.

How do You Calibrate a Force Sensing Resistor?

Because of their resistance/conductance linear relationship, force sensing resistors can be calibrated with as little as two-to-three known loads. This article explains the step-by-step calibration process in detail.

Also, if your circuit is designed with adjustable components, the sensor’s sensitivity can be adjusted for optimal performance in your specific force range. This article provides further details on the value of adjustable sensitivity.

How are Force Sensing Resistors Made?

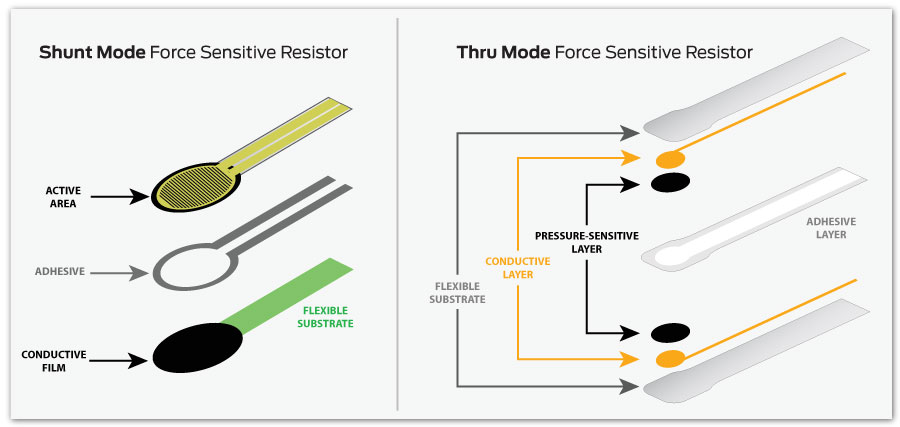

Force sensing resistors consist of a semi-conductive material – or, semi-conductive ink – contained between two thin substrates. As shown in Figure 2, there are two different types of force sensing resistor technologies – Shunt Mode, and Thru Mode.

Figure 2: This graphic illustrates the differences between shunt and thru mode force sensing resistor technologies.

Figure 2: This graphic illustrates the differences between shunt and thru mode force sensing resistor technologies.

Shunt mode force sensing resistors are polymer thick-film devices consisting of two membranes separated by a thin air gap. One membrane has two sets of interdigitated traces that are electronically isolated from one another, while the other membrane is coated with a special textured, resistive ink.

Thru mode force sensing resistors are flexible printed circuits that utilize a polyester film as its two outer substrates. Silver circles with traces are positioned above and below a pressure-sensitive layer, followed by a conductive polymer. An adhesive layer is used to laminate the two layers of the substrate together.

Matrix or Single-Point Force Sensing Resistors

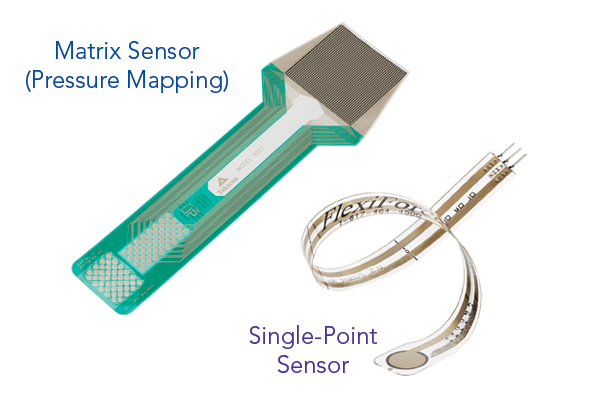

Figure 3: Examples of different force sensitive resistor technologies.Force sensing resistors can be designed as single-point force sensors, or in a matrix array form, allowing the user to capture pressure distribution over a given area. Force sensing resistor matrices are commonly referred as pressure mapping technology.

Figure 3: Examples of different force sensitive resistor technologies.Force sensing resistors can be designed as single-point force sensors, or in a matrix array form, allowing the user to capture pressure distribution over a given area. Force sensing resistor matrices are commonly referred as pressure mapping technology.

FlexiForce™ sensors from Tekscan are a thru mode force sensing resistor variety. The flexibility of this technology, combined with their operating capabilities, and their ability to function on simple circuitry, make them a great option for embedding into smart devices with limited space and power constraints. FlexiForce sensors are also highly customizable. The shape, size, sensitivity, electrical termination, and operating temperature, can all be tailored to your application’s specific needs.

How Do Different Force Sensing Technologies Compare for Accuracy?

This article covers the difference between FSR technologies for several performance differences between shunt and thru mode sensor technologies.

There are significant differences in accuracy in areas such as linearity, drift, precision, dynamic range, sensing area dependence, and other key factors as validated by 3rd party researchers.

How are Force Sensing Resistors Used?

While new uses for force sensing resistor technology are being discovered every day, most applications tend to fall under four different use categories:

- Detecting or measuring a rate of change in force

- Detecting or measuring a relative change in force

- Detecting contact and/or touch

- Detecting force thresholds to trigger an action of some sort (e.g., IoT applications)

This short video provides more visual context around these different use cases for force sensing resistors – specifically FlexiForce force sensing resistors:

If you are an engineer designing a new device that requires compact force sensing, our force sensors for design ebook lays out all the considerations needed for comparing force sensor technologies, power consumption, cost, size, and durability. It also includes real life examples of device integrations of flexible, compact force sensors, and the value of engineering support when choosing a critical sensor integration.

Are You Interested in Purchasing Force Sensing Resistors?

At Tekscan, we offer a range of standard FlexiForce force sensing resistors in low-cost, low-quantity packs, from our online store. We also offer force measurement systems and OEM proof-of-concept and integration kits to assist you in your diverse force measuring needs.

For any other questions on force sensing resistor technology, contact a Tekscan engineer today!

Previous Post: | Next Post: |