Background

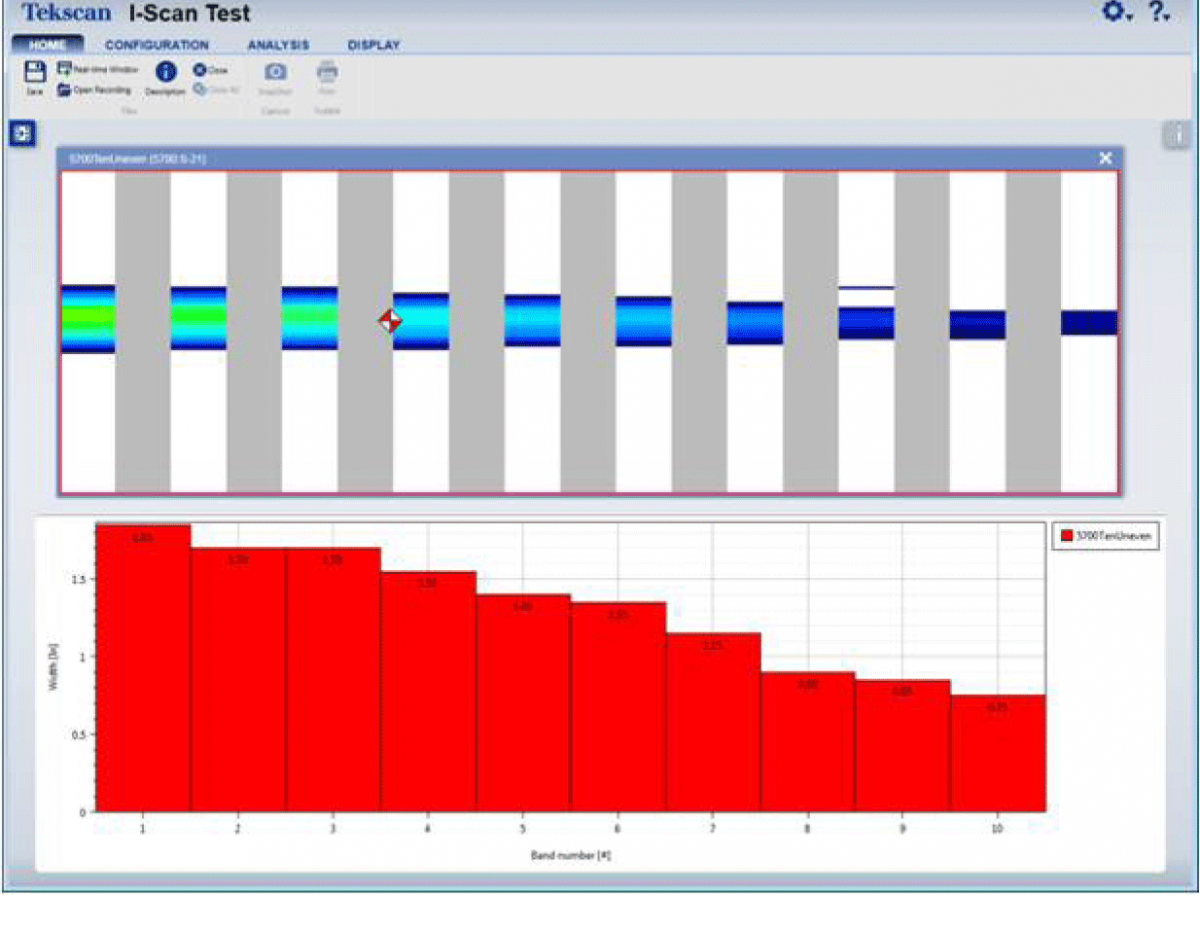

Having proper nip roll alignment is crucially important for high-volume printing press machines. Five minutes of run time on misaligned rolls can result in thousands of dollars in damaged product. Depending on the size and location of the nip, taking nip measurements can be difficult tasks.

Challenge

To incorporate technology that ensures proper nip roll alignment, streamlines setup processes, reduces production downtime, and ensures product quality.

Solution

A production line integrated with pressure mapping technology can provide fast, actionable data on the nip crown, diameter variation, and deflections. Software embedded into the machine’s user interface can help the operator pinpoint specifically where the nip should be adjusted, thus reducing costs from material loss. Whether you need a full nip pressure alignment tool system, or a more flexible pressure measurement solution for small nip rollers and high temperature applications, we can help.

Other similar applications:

- Paper printing

- Laminating

- Smart Labels

- Textiles

- Packaging

- Converting