Versatile Pressure Mapping System

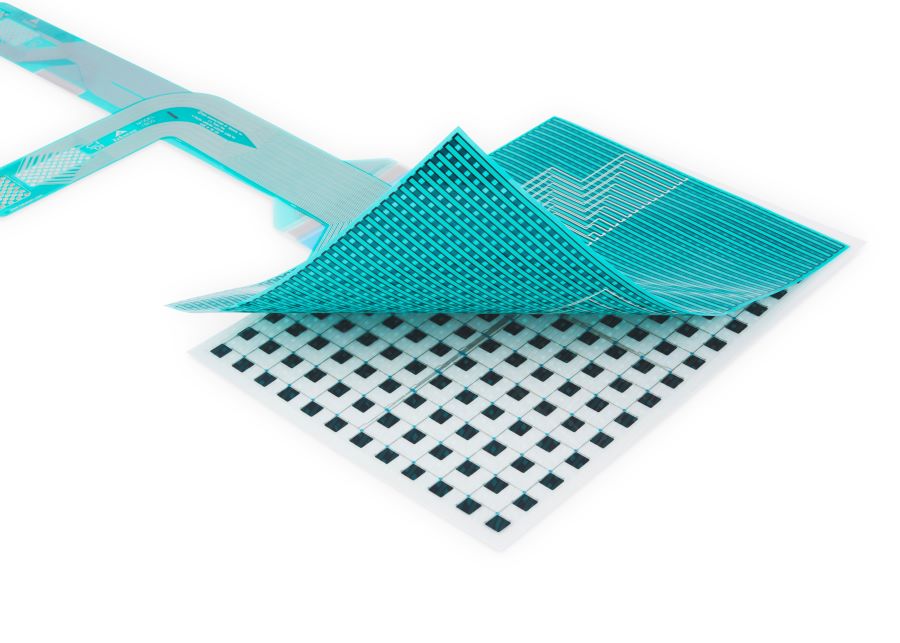

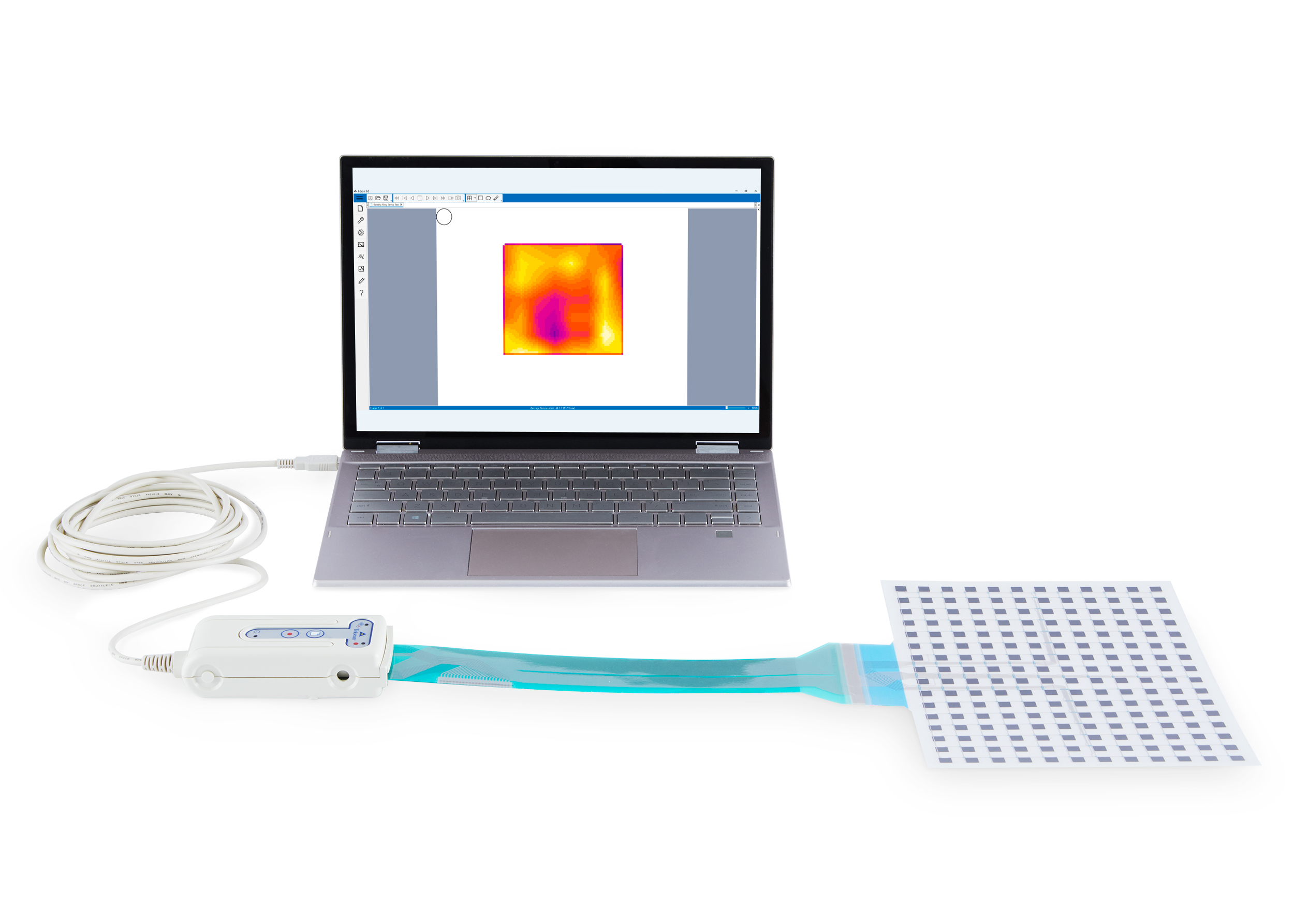

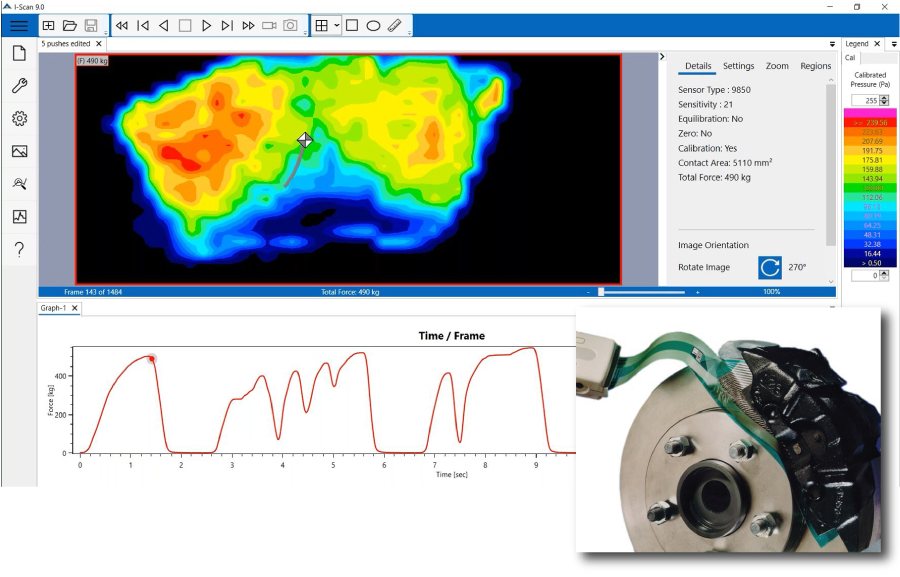

I-Scan™ is a powerful tool that accurately measures and analyzes interface pressure between two surfaces, utilizing a thin and flexible sensor. The system is comprised of data acquisition electronics, sensors, and software. Measuring both force and pressure, the exceptionally thin tactile sensor provides minimal interference between the objects being measured, allowing the true interface pressure data to be obtained. The interface pressure data collected offers vital information and insight to enhance product design, manufacturing, quality, and research.

Accurate, repeatable pressure measurement is the foundation for better designs, faster validation, and smarter manufacturing decisions. By capturing dynamic interface pressure data with thin, flexible sensors, I-Scan provides a reliable digital record of how products and processes perform under real-world conditions. This data allows engineers and manufacturers to:

- In-depth understanding of surface behavior

- Verify forces and peak pressures between two components

- Measure external forces

- Reduce failures & associated costs

- Verify calibration of machinery

- Improve repeatability of processes

- Reduce downtime & improve yields

- Identify potential failure modes

- Quality inspection & control

- Competitive benchmarking

- Understand the physical properties of the objects being measured

- Understand the pressure distribution between two surfaces

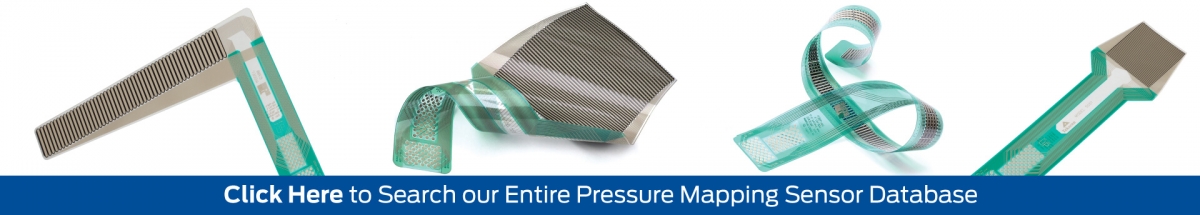

Over 200 flexible, thin film tactile pressure sensors are available in different sizes, shapes, resolutions, temperature ratings, and pressure ranges (up to 25,000 psi or 1,700 bar).

Watch this short video covering the Top-6 Most Popular I-Scan Sensors

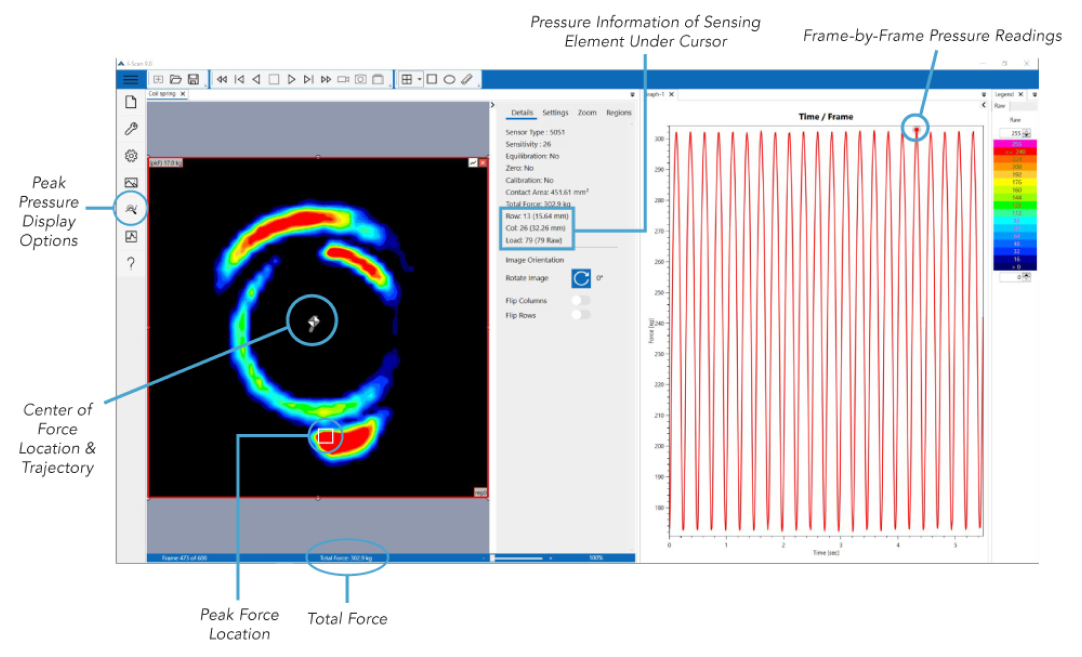

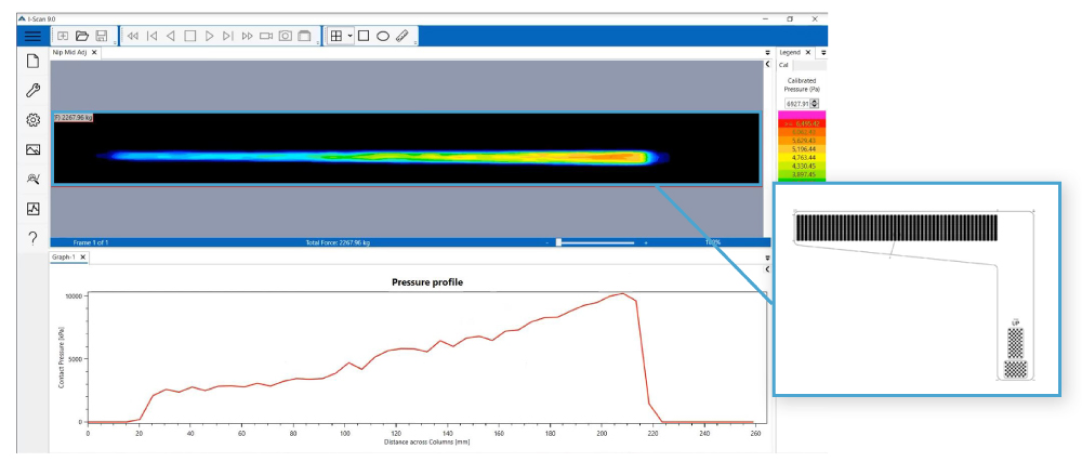

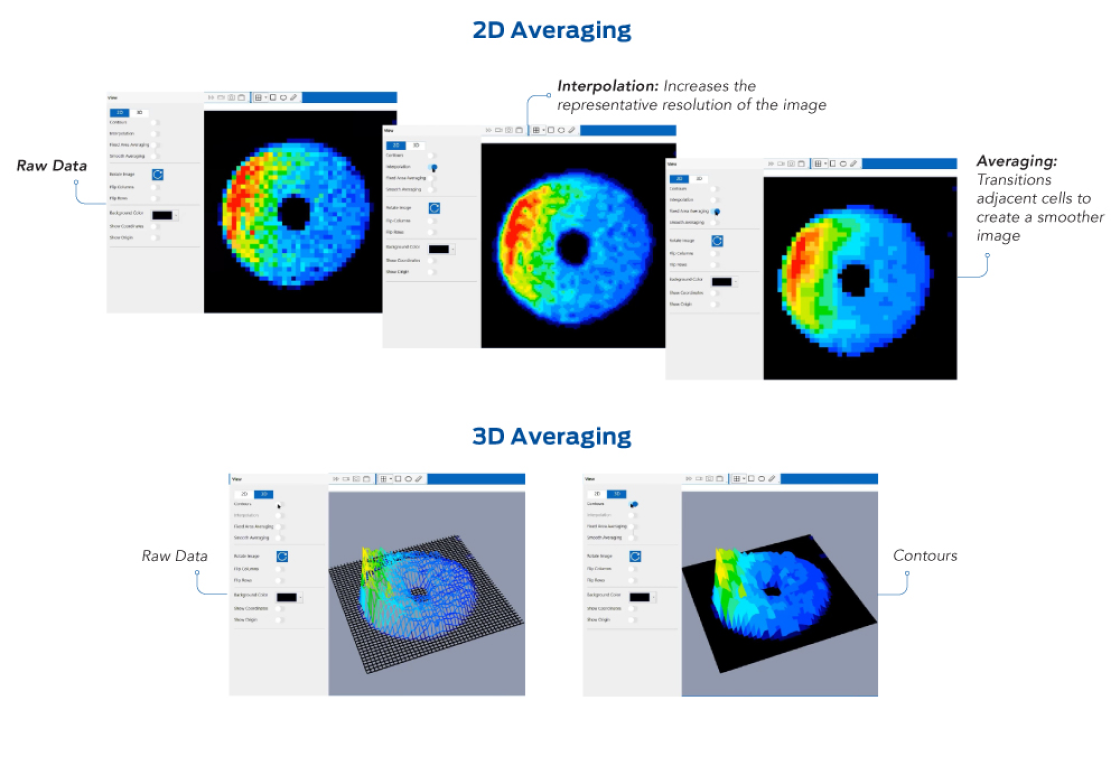

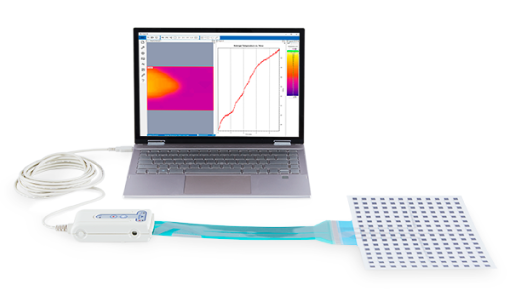

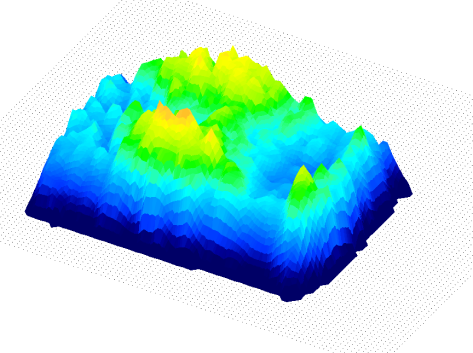

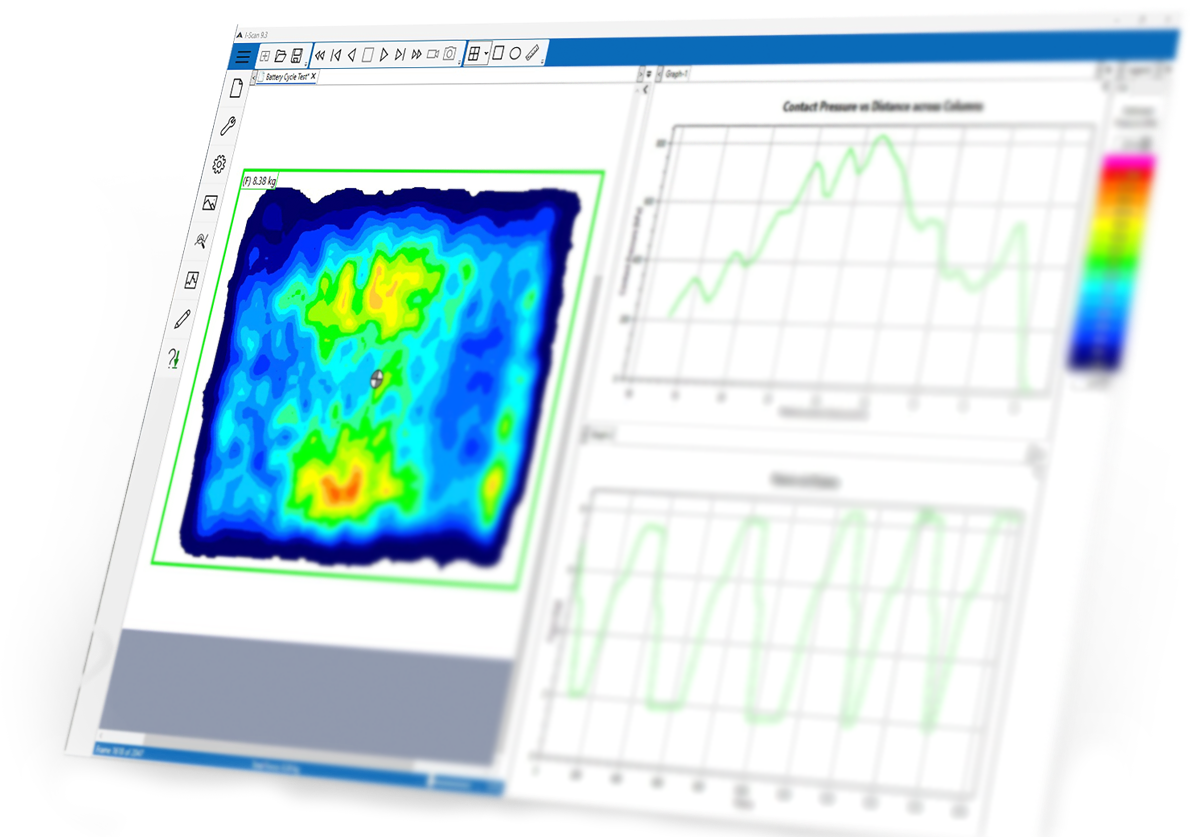

I-Scan™ provides the tools for more comprehensive and higher quality analysis than ordinary pressure sensing technologies.The software displays the pressure distribution data, in multiple formats, for superior analysis.

Graphic & Data Analysis

With the ability to capture force over time, users can click at any point of a pressure mapping recording to view the resulting pressure output image.

Data from each frame includes:

- Total force

- Center of force location

- Peak pressure

- Pressure distribution (e.g., force on each sensing element)

Sensor MAPs

Each sensor requires its own unique MAP driver file for the software to function properly. By utilizing sensor MAPs, the software is able to provide an accurate depiction of each unique sensor layout. The sensor MAP controls the shape of the pressure image window in the software, which corresponds to the shape and dimensions of the sensing area on the sensor.

I-Scan Evolution software can run from a Windows computer or tablet.

Unique Applications for the I-Scan System

Are you interested in finding out how I-Scan can provide the impactful insights from surface sensing you need to make more informed decisions? Complete the form to: Ask a quick question Schedule a demonstration Request a quote

Complete the form to:

- Ask a quick question

- Schedule a demonstration

- Request a quote