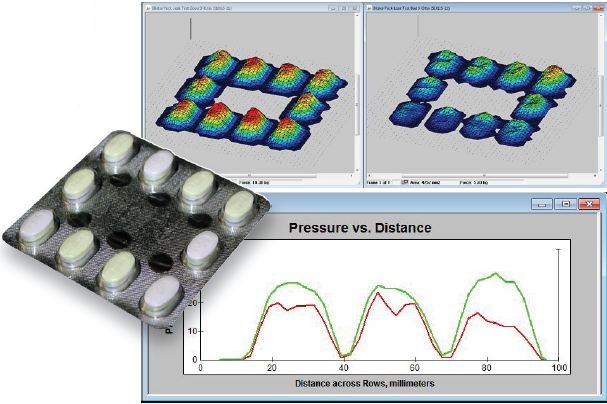

Pressure Mapping technology helps engineers improve overall quality control in the production area and gives them insight into machine set-up. This data provides manufacturers with actionable data that helps to optimize the manufacturing process.

This free eBook demonstrates the importance of interface pressure measurement and explores a variety of packaging applications including:

- Sealing Jaw

- High Temperature Sealing Bar

- Bag Seal

- Package Drop/Impact

- Package Stacking

- Ultrasonic Welding

- Sealing Die Measurement

- Tool Die Setup

- Package Assembly

- Blister Pack

- Integrating Pressure Mapping into Packaging Machines

Tekscan systems can determine the effectiveness of your seal by testing the pressure produced by the clamp during the sealing process.

![[Before and After Adjustment] Pressure Mapping in Packaging Applications](/sites/default/files/packaging-application-pressure-mapping.jpg)

Packaging: Gaining Insight Into Your Process With Pressure Mapping