Background

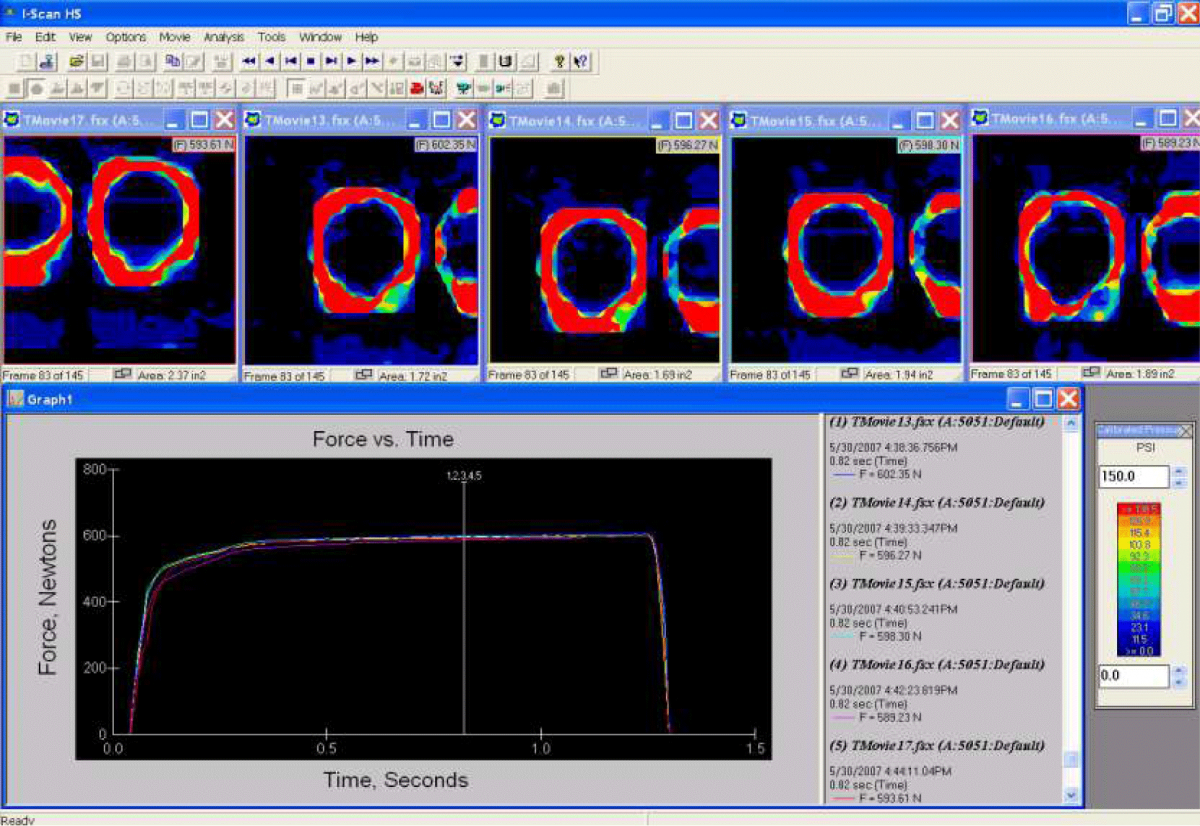

Ultrasonic welding machines are used to create uniform seals, which are vitally important for containing products like contact lenses. In the ultrasonic welding process, thermoplastics are bonded together through the use of heat and applied force. A damaged seal can result in leaky packaging, rendering the product unusable in some cases.

Challenge

To design a contact lens packaging machine that ensures a proper ultrasonic welding seal. In doing so, the machine can help the operator eliminate losses and maintain product consistency with every production run.

Solution

Integrating pressure mapping technology into a machine’s user interface can help streamline the contact lens packaging machine’s setup process. The manufacturer can gain insight into the seal’s pressure distribution to confirm that every individual contact lens is packaged securely.

Other similar applications:

- Pressure welding for medical device manufacturing

- Single serve packaging

- Toy manufacturing

- Any form, fill, and seal application