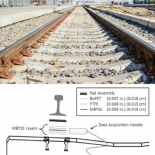

Figure 1: This diagram shows how the pressure mapping sensor (MBTSS) was positioned between the concrete rail seat, and bottom of the rail pad.

Figure 1: This diagram shows how the pressure mapping sensor (MBTSS) was positioned between the concrete rail seat, and bottom of the rail pad.

Designing railroad ties to keep up with the increase in rail loads and freight tonnage in worldwide railway infrastructure is a demanding engineering application.

Researchers at the University of Illinois Rail Transportation and Engineering center used Tekscan pressure mapping technology to collect rail pressure seat data to aid in the development of more robust concrete sleeper and fastening component designs.

This paper published by C. T. Rapp, et. al, at the University of Illinois at Urbana-Champaign Rail Transportation and Engineering Center details their experiments using Tekscan systems for matrix-based tactile surface sensors. Read the study to learn their conclusions on managing rail seat loads.