How does the level of accuracy change as curvature of surfaces increases?

Question: How does the level of accuracy change as curvature of surfaces increases? In other words, what level of curvature causes so much crimping in the sensor that readings lose accuracy? Is contact area affected by the curvature or does this just affect the pressure readings?

Answer: Curvature or wrinkling of the sensor will produce a preload on the sensor. This will affect both the pressure readings and the measured contact area. The extent of this preload is dependent on the radius of curvature and on the pressure range of the sensor. Sensors with lower pressure ranges are more sensitive and will be more inclined to produce readings induced by curvature of the sensor.

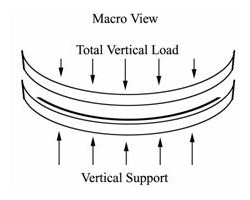

Curved Contact Surfaces When studying contact between soft or curved objects such as the foam of a bed or chair and human flesh, or artificial knee joints, calibrate with the objects being studied, not with an equilibrator. That way the curvature that evolves between the surfaces in calibration is similar to the curvature of the experiments. To better understand this, consider a free body diagram of a concave curved surface supporting a convex vertical load. The total resulting vertical force vector results from many individual local vectors with opposing horizontal components, which cancel out. Tekscan sensors respond to the individual local normal forces, and the software sums these forces (assuming the sensor is flat).

Tekscan sensors are made with s dimensionally stable substrate: polyester sheet. A dimensionally stable sheet rolls nicely around a simple curve such as a cylinder or cone. Thus, measurements can easily be taken on a coffee cup, rolling pin, or the body of a ballpoint pen. A dimensionally stable material has difficulty wrapping smoothly over a ball, or someone´s nose or chin. If the sensor crinkles, or develops folds, it is prone to report high-pressure output where little or no pressure is applied. These locations may be “tared out”, the bottom threshold of the legend can be raised, or they can be edited out of the movies altogether.

When loading soft interfaces, such as a crash dummy or a person onto a foam/cushion, try to calibrate with the actual materials and with the actual profiles/curvature. Curved contact surfaces with complex curves may be measured with Tekscan´s sensor models 6900, 9801, or 9830 since they have narrow sensing areas (“fingers’) that lend themselves to positioning on contoured surfaces with minimal artifact generated from the geometry.