Survey Results for Drug Delivery Systems

Medical Device Design Engineers Say Sensor Accuracy Trumps Cost

In March 2011, Tekscan, Inc. teamed up with medical device media company Canon Communications to conduct a survey among design engineers in the medical device industry. In recent years, Tekscan, Inc. has recognized an increased demand for thin and flexible force sensors in the medical device market. This demand has particularly increased for applications involving companies who are in the market for a force sensor to incorporate into a new product or as part of a product re-design. Such products include drug delivery systems such as infusion pumps, as well as more novel systems such as minimally invasive fine-gauge needle systems.

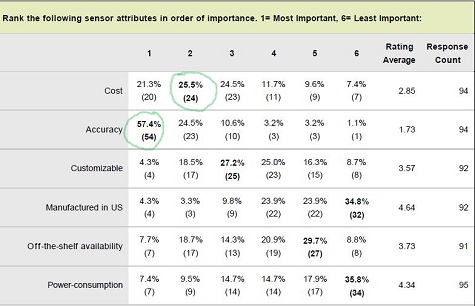

The survey results shed light on the challenges faced by product designers in this market, particularly as they relate to sourcing and integrating components like sensors. Engineers ranked a list of sensor attributes in order of importance on a scale of 1-6 (one being most important, 6 being lease important): cost, accuracy, customizable, manufactured in the US, off-the-shelf availability, and power-consumption.

According to the survey results, the top three sensor attributes in order of importance are:

- Accuracy (57.4% chose this as the #1 sensor attribute). Average rating = 1.73

- Cost (25.5% chose this as the #2 sensor attribute). Average rating = 2.85

- Customizable (27.2% chose this as the #3 sensor attribute). Average rating = 3.57

What does this mean for engineers seeking an accurate, cost-effective, customizable force sensor?

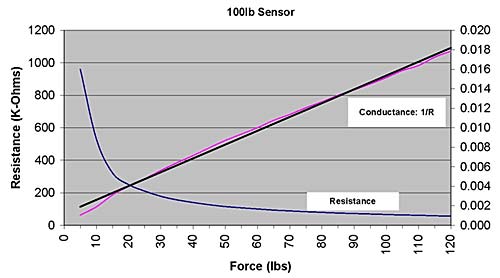

Of the thin, flexible tactile sensors on the market, the FlexiForce™ sensor exhibits the highest degree of linearity (the linearity error ranges from ±1.2% to ±3% depending on the sensor model). Its ultra-thin profile (0.008”) and customizable form factor make it ideal in applications with weight and size restrictions.

Linearity of FlexiForce sensor depicted in above force vs. resistance/conductance chart

The most widely-known instruments for measuring force are load cells. Strain gauges, piezoelectric elements, and variable capacitance are all examples of load cell technology. While load cells offer very precise measurements, they can be bulky, which is a drawback in applications where weight and size are at a premium. In many applications, the highly precise measurements offered by load cells are not necessary.

As one FlexiForce customer states:

“From all the available force-sensing technologies, we selected the FlexiForce as the best combination of durability, price, and accuracy…As long as measurements lay within a few ounces, it was good enough. Load cells proved too big because they interfered with system operation.”

Another advantage of tactile sensor technology like FlexiForce is that it is a lower-cost option than a traditional load cell. Available off-the-shelf for testing, Tekscan offers volume discounts and custom options for OEM customers. Standard sensors are single-point sensors with either a 0.375 in diameter or 1 in diameter. Custom force sensors can be created in various shapes or sizes, and can contain multiple sensing points.