Tekscan Technology

Tekscan technology encompasses sensor technology, data acquisition electronics, and processing and analysis software. Tekscan has numerous patents, copyrights, trademarks, and/ or patents pending supporting our intellectual property claims.

|

Sensor Technology |

|

Data Acquisition Electronics |

|

Data Acquisition, Display, & Analysis Software |

Single-Point Force Sensors

Tekscan manufactures thin-film sensors to measure between any two mating surfaces. The thinness of these sensors is unparalleled in the industry allowing for a true interface measurement.

| Force Sensors (FlexiForce™ Touch Sensors) | Position Sensors (FlexiPot™ Sensors) |

FlexiForce Touch Sensors FlexiForce Touch Sensors |

FlexiPot Position Sensor FlexiPot Position Sensor |

|

FlexiForce™ force sensors can measure force between almost any two surfaces and are durable enough to stand up to most environments. Our force sensors are available off-the-shelf for prototyping or we can customize to meet your specific requirements. FlexiForce Sensors are:

|

The FlexiPot™ Strip and Ring tactile potentiometers and/or position sensors are used to identify location or position and adjust output. These sensors can measure position between any two surfaces. FlexiPot Sensors are:

|

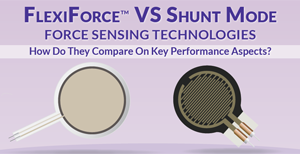

FlexiForce offers significant performance advantages when compared to other force sensing resistor technologies - including shunt mode technology.

This infographic explains more

Matrix Pressure Sensors (Pressure Mapping Sensors)

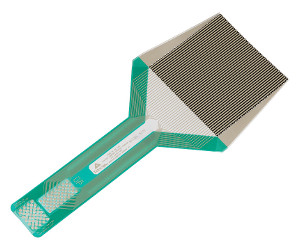

Our pressure mapping systems measure interface pressure between two surfaces, utilizing a thin and flexible sensor. The resulting data and our analysis tools offer insights to enhance product design, manufacturing, quality, and research.

- Map interface pressure

- Analysis tools provide insight for a better understanding of surface behavior

- Sensors, data acquisition electronics, and software can all be customized to align with application needs

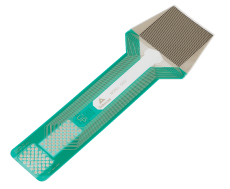

Sensors

|

Electronics

|

Software

|

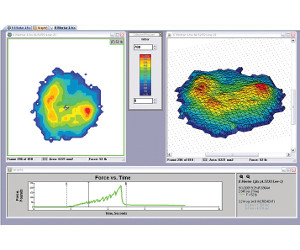

Matrix Temperature Sensors (Temperature Mapping Sensors)

Tekscan has enhanced the I-Scan™ platform with a new thin-film temperature mapping capability, enabling you to capture detailed temperature distribution across a surface—or in between two surfaces where thermal cameras can’t, and where thermocouples would be difficult to use.

This is a new category of temperature sensing system that lets you:

- Visualize thermal propagation - Identify how heat moves through a surface and pinpoint critical area for optimization in product design, material selection, and process control.

- Correlate temperate and pressure - Overlay with I-Scan Pressure Mapping to reveal critical relationships between pressure and temperature affecting product performance and reliability.

- Measure temperature where you previously could not - Accurately measure temperature in moving components, enclosed spaces, and multi-layer materials – even inside sealed machinery and rotating rollers where infrared cameras fail or thermocouples are difficult to place.

.

Have a unique application that calls for a unique sensor? Check out this short video on our Pressure Mapping Sensor Customization Process

How a Matrix Sensor is Made

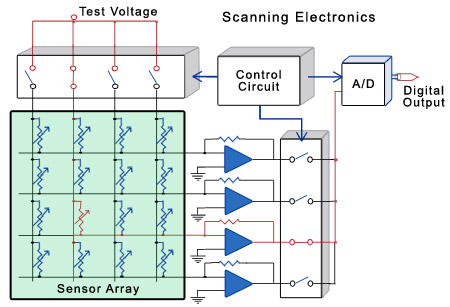

Pressure mapping sensors are ultra-thin pressure-sensitive resistors (aka, tactile array sensors) that are used capture pressure data between nearly any two surfaces. Each sensor consists of intersecting rows and columns of conductive material. At each intersection is a layer of pressure-sensitive material. As pressure is applied to the sensing area, the resistance of the pressure-sensitive material changes. Scanning electronics connected to the sensor collects and converts this resistance change into digital signal, which is then transmitted to a computer for real-time analysis.

Tekscan Sensor Properties & Performance

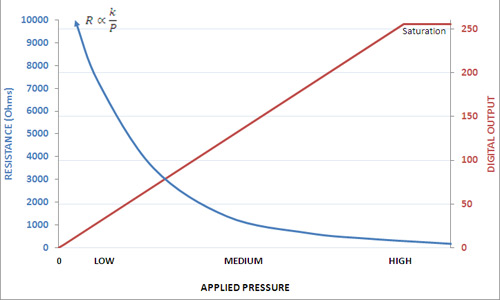

Figure 1: Typical Sensor PerformanceMatrix sensors (arrays) are available in a wide variety of shapes and sizes. They are also available in various pressure ranges from 0-14 kPa to 0-207 MPa. Custom designed shapes, sizes, and sensitivities are also available. Typical system performance is shown in Figure 1.

Figure 1: Typical Sensor PerformanceMatrix sensors (arrays) are available in a wide variety of shapes and sizes. They are also available in various pressure ranges from 0-14 kPa to 0-207 MPa. Custom designed shapes, sizes, and sensitivities are also available. Typical system performance is shown in Figure 1.

- Resistance of the sensing elements (Sensels™) varies inversely with applied load.

- The system linearizes sensor output into digital counts, or “raw” values on a scale from 0-255.

- Calibration converts raw values into engineering units, such as psi or kPa.

| Sensor Property | Standard | High Temperature (*Custom Production Run Required) |

|---|---|---|

| Linearity | <±3% | <±1.2% |

| Repeatability | <±3.5% | <±3.5% |

| Hysteresis | < 4.5% of full scale | < 3.6% of full scale |

| Drift per log time | 5% | 3.3% |

| Lag Time | 5 µsec | 5 µsec |

| Operating Temperature | -40° to 140°F (-40° to 60°C) | Up to 400°F (200°C) |

| Thinness | 0.004 in (0.1 mm) | 0.008 in (0.2 mm) |

| Sensel Density |

Up to 1,600 per sq. in. (248 per sq. cm) (0.6 mm) |

Up to 400 per sq. in. (61 per sq. cm) (1.27 mm) |

| Pressure Range |

Up to 30,000 psi (207 MPa) (dependent on sensor selection) |

Up to 3,000 psi (20.7 MPa) (dependent on sensor selection) |

Data Acquisition Electronics

Figure 2: Electronics SchematicTekscan’s interface products employ sophisticated microprocessor based circuitry to control scanning sequence and frequency, adjust sensitivity, and optimize the performance of matrix-based sensors.

Figure 2: Electronics SchematicTekscan’s interface products employ sophisticated microprocessor based circuitry to control scanning sequence and frequency, adjust sensitivity, and optimize the performance of matrix-based sensors.

Figure 2 demonstrates the sensing system and a simplified electrical schematic of the 8-bit electronics (255 levels) that scan the intersecting points of the sensor’s rows and columns and measure the resistance at each crossing point or sensing element (Sensel). The Sensels are read in the presence of multiple contacts while simultaneously limiting the possible current flow through the device. Each Sensel is represented by a variable resistor whose value is highest when no force is applied to it.

Tekscan systems have different options for electronics depending on the application requirements.

Tethered Electronics (USB 2.0 Connection)

|

|

Used for standard applications, this system is lightweight and versatile. The Evolution™ scanning electronics consist of a handle that connects to a sensor and to the USB port of a PC. Multiple handles may be used simultaneously. Indicators on the handle show system status and allow some control of data collection.

|

|

|

Used for larger sensors with multiple tabs or high speed applications. The VersaTek™ scanning electronics consist of a handle that connects to a sensor and to an 8-port hub, which then connects to the USB port of a PC. The hub drives and collects signals from up to 8 handles simultaneously.

|

Wireless Electronics (compatible with VersaTek electronics only)

Note: Same unit is used for either wireless or Datalogger configurations. Note: Same unit is used for either wireless or Datalogger configurations. |

Wireless VersaTek Unit - directly transmits data wirelessly from unit to PC

Datalogger VersaTek Unit - stores data within the data collection unit for upload to PC at a later time

|

These options have differences such as maximum scanning rates and it is recommended you discuss your application requirements with your Account Manager to select the appropriate product.

Learn more about Data Acquisition Electronics including complete product specifications

Software – The Power of Information

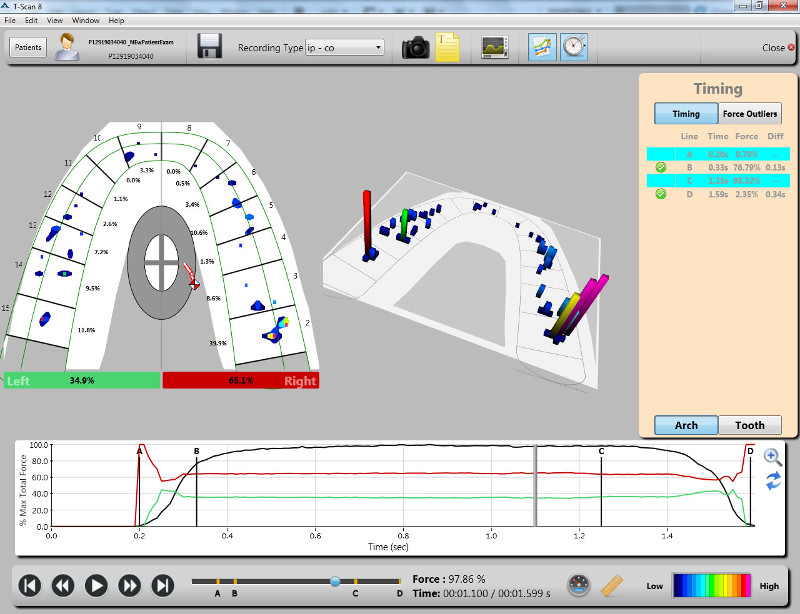

T-Scan Digital Occlusal Analysis Software

T-Scan Digital Occlusal Analysis Software

Tekscan's products function in both static and dynamic measurement environments. Our customers are interested in the temporal development of load profiles and peak load attainment, as well as the relaxation characteristics of materials and interfaces.

- Each system is capable of sampling thousands of Sensels per second

- Our standard I-Scan™ system can sample 250,000 Sensels per second.

- Tekscan also has higher performance systems which sample 100,000 Sensels at 500 Hz - an astounding 50,000,000 Sensels per second!

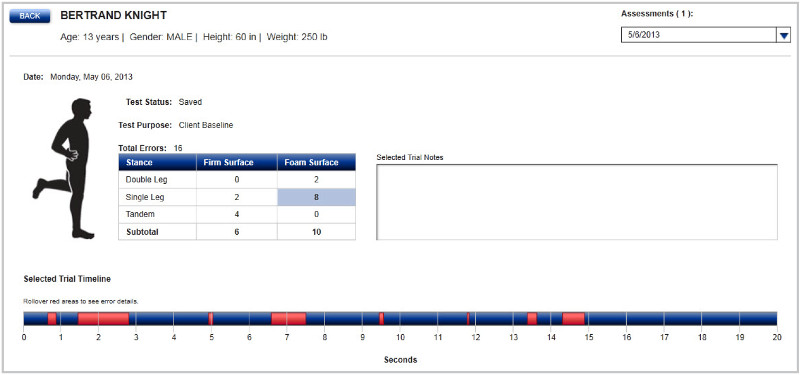

Sports AT Software for Balance Error AssessmentHigh-Speed Systems

Sports AT Software for Balance Error AssessmentHigh-Speed Systems

Tekscan’s high-speed systems are simplified matrices or single load cell configurations. The current maximum sampling rate for an integrated system is 20 kHz in a 44 load cell configuration. This high sampling rate is possible due to the extreme thinness and the relatively high spring constant of our sensor materials (a rise time of less than 20 microseconds). The ability to directly instrument the impact surface greatly enhances overall test accuracy. No other system solution is as adaptable and affordable.

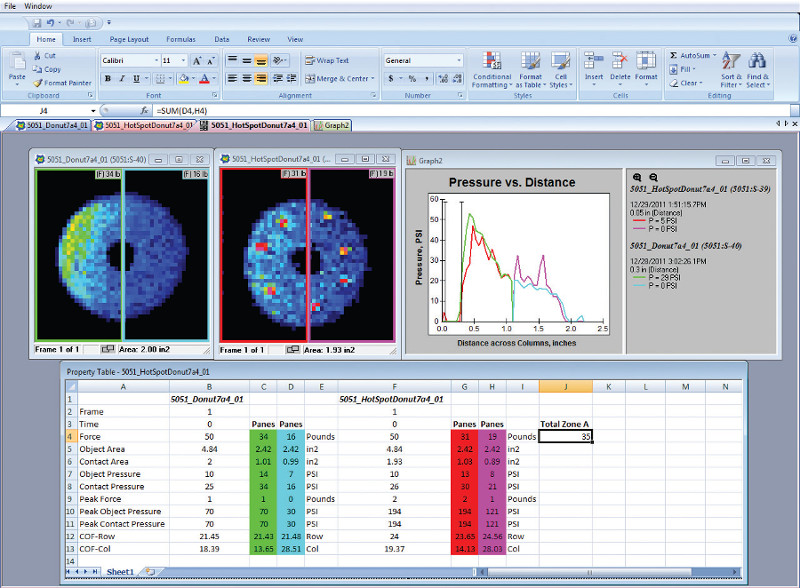

I-Scan Pressure Mapping SoftwareMaking this possible is Tekscan’s custom data acquisition electronics and software. The data acquisition software consists of low level sampling control, sensitivity adjustment, and signal processing. This software optimizes the performance of the system in the acquisition of force or pressure data from our matrix-based and FlexiForce sensors.

I-Scan Pressure Mapping SoftwareMaking this possible is Tekscan’s custom data acquisition electronics and software. The data acquisition software consists of low level sampling control, sensitivity adjustment, and signal processing. This software optimizes the performance of the system in the acquisition of force or pressure data from our matrix-based and FlexiForce sensors.

With its Windows®-compatible software, the Tekscan system is simple to operate. Whether you choose a standard or a custom package, your system will respond quickly to your most important and frequent needs with graphically informative displays and intuitive operations.