Tekscan Announces Latest Patent for Portable Tire Contact Sensors

FOR IMMEDIATE RELEASE

Elizabeth Hood, Senior Strategic Marketing Manager

Tel: 617-464-4500 x223 Email: ehood@tekscan.com

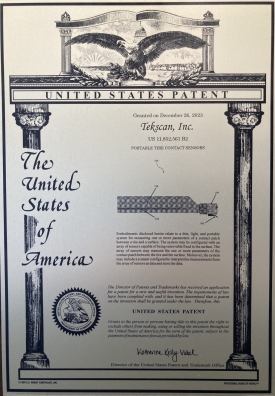

Tekscan Announces Latest Patent for Portable Tire Contact Sensors

Norwood, MA. February15, 2024

Tekscan is excited to announce our most recent patent acquisition for portable tire contact sensors. This innovation is integral to our groundbreaking High Speed TireScan system. This milestone marks our 18th patent, underscoring Tekscan’s continued commitment to advancing pressure sensing technology in the industry.

The patent reads as follows:

Embodiments disclosed herein relate to a thin, light, and portable system for measuring one or more parameters of a contact patch between a tire and a surface. The system may be configured with an array of sensors capable of being removable fixed to the surface. The array of sensors may measure the one or more parameters of the contact patch between the tire and the surface. Moreover, the system may include a scanner configured to interpret the measurements from the array of sensors as data and store the data.

BACKGROUND

The size, shape, and pressure distribution of a contact patch between a tire of a vehicle and a surface is a function not only of the load, speed, and direction of the vehicle, but also of the design of the tread pattern and the materials used in the tire itself. Because of the influence of the contact patch on the ultimate performance of the vehicle, tire manufacturers may employ methods to observe and measure the contact patch in both actual (e.g., on road) and simulated test conditions.

Generally speaking, a tire manufacturer may employ one or more known methods of collecting data related to the contact patch of a tire. For example, conventional methods include simple solutions such as rolling ink onto the tire surface and rolling the inked tire on a sheet of paper. Other conventional methods include simulating a road surface using a cast iron drum or taking a picture of the contact patch using a camera system mounted to a transparent plate.

The High Speed TireScan system was launched last year to help tire designers model pressure changes at high speeds. With the introduction of this lightweight but rugged system, tire manufacturers and testing facilities can now accurately, repeatably, and efficiently measure dynamic contact patch pressure (DCPP) information from a tire running on a belt at speeds up to 165 mph (265 km/h).

###