Balancing Squeegee Pressures Using Pressure Measurement

Challenge

A misaligned squeegee can lead to poor print quality, inconsistency, and considerable product defects, increasing costs and product waste.

Solution

The I-Scan™ force and pressure mapping system is a key diagnostic and machine set-up tool for balancing squeegee pressures. The system's minimally intrusive sensors can be positioned under the screen or squeegee blade to adjust blade height, pressure and tightness, ensuring the desired pressure distribution along the length of the blade is achieved.

The I-Scan pressure mapping system allows for real time viewing of the pressure along the squeegee blade and can also capture and display the pressure pattern from the entire print stroke as the blade traverses the screen during the printing stroke cycle. If the squeegee is unbalanced during the stroke, alterations can be made and new measurements taken. Using this system, an unbalanced squeegee blade can be detected prior to use, saving your company money and time. With the help of Tekscan's highly qualified sales and engineering support team, each system may be configured to meet your specific needs.

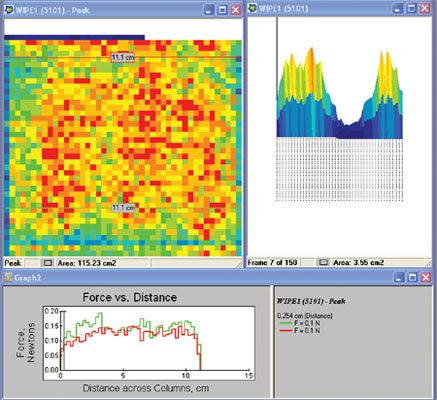

2D and 3D display of the pressure output of a squeegee during the solder paste stenciling and screen-printing operation in PCB manufacturing.

2D and 3D display of the pressure output of a squeegee during the solder paste stenciling and screen-printing operation in PCB manufacturing.

Squeegee Pressure Measurement Applications

- Squeegee blade balancing

- Correlate output quality to set-up

- Machine set-up and adjustment

Benefits of Pressure Mapping

- Faster machine set-up

- Increased product yields

- Improved product quality

- Improved print consistency