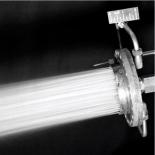

Spray Pattern Pressure Measurement

Challenge

Distribution of the spray from a nozzle is important, but difficult to quantify. A nozzle manufacturer needs to meet their customer's needs. Selling a too high pressure nozzle might cause damage to property or injure people. Developing a low pressure nozzle might not get the job done.

Solution

In a test, the I-Scan™ pressure mapping system can measure and record pressure spray patterns, and support analysis so adjustments can be made. I-Scan pressure mapping data can be used to develop new conceptual designs, conduct quality control tests, benchmark nozzle characteristics and document the effectiveness of proprietary solutions. Sensors are available in different shapes, are reusable, and provide accurate pressure readings. With the help of Tekscan's highly qualified sales and engineering support team, each system may be configured to meet your specific needs.

Spray Pattern Pressure Measurement Applications

- Identify peak pressures, localized pressure, and pressure distribution patterns

- R&D for new spray nozzle designs

- Competitive bench-marking

- Quality assurance

- Spray coverage

Benefits of Pressure Mapping

- Precise measurement of spray pressure, magnitude and location

- Real-time viewing of spray

- Quickly measures spray