How to Test FlexiForce Sensors for OEM Applications

Ed Haidar; Tekscan Applications Engineer and Product Manager for the FlexiForce Embedded Sensing Division.For designers and engineers, the measures taken early in the sensor integration process can make a significant impact in the later design phases. While some embedded components companies provide collateral and documentation validating sensor performance, always keep in mind that every application is unique. What may work for some may not always translate to other projects or designs.

Ed Haidar; Tekscan Applications Engineer and Product Manager for the FlexiForce Embedded Sensing Division.For designers and engineers, the measures taken early in the sensor integration process can make a significant impact in the later design phases. While some embedded components companies provide collateral and documentation validating sensor performance, always keep in mind that every application is unique. What may work for some may not always translate to other projects or designs.

Having worked closely with many engineers and OEMs throughout the years, one of the crucial first-steps in the FlexiForce sensor integration process that often goes overlooked is Sensor Characterization. Designers and engineers that begin their integration process with a proof-of-concept or prototyping, without first characterizing their sensor technology of choice, may run the risk of challenges along the way.

What is Sensor Characterization?

Sensor characterization is the process of establishing a fundamental understanding of sensor functionality in a controlled, known loading environment. During this process, engineers and designers are collecting a topline assessment of sensor linearity, hysteresis, drift, and repeatability under different circuitry and interfacing materials.

Engineers and designers perform sensor characterization in order to answer two core early-stage design questions:

- What is the fundamental performance of the sensor technology?

- How does the sensor perform with the circuits and material interfaces considered for the application?

Why is Sensor Characterization Important?

As I mentioned earlier, every application is unique. Taking the time to characterize sensor performance – even though it may seem time-consuming at first – means that you have trustworthy baseline data you can reference throughout your design-in process. This is extremely important when troubleshooting or debugging challenges that can arise in later integration phases.

Case Example: We recently worked with a customer that was trying to embed a FlexiForce sensor within a handheld medical device. There was an adhesive holding the sensor in place, while an actuator would apply force to the sensor. During field testing, they noticed that the sensor was not outputting optimal performance in warmer and more humid climates.

Rather than dismiss the FlexiForce sensor, they brought the prototype back to their testing lab. When matched with the characterization data they took earlier, the sensor from the defective prototype appeared to be performing as it should. They instead chose a different adhesive for their prototype, instead of doing a complete redesign, and the next phases of field testing were a success.

What do you recommend for Characterizing FlexiForce Sensors?

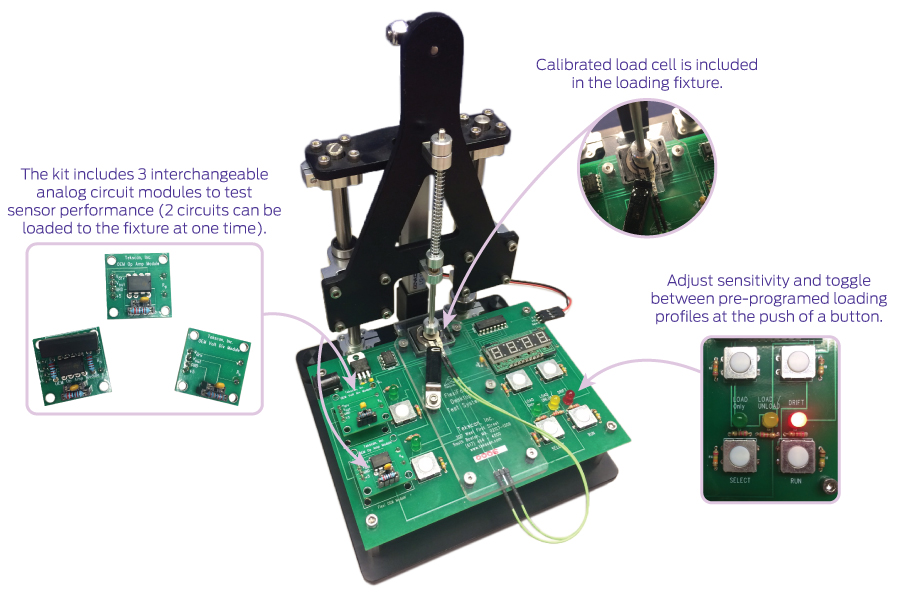

We recently introduced a new product to help OEMs in their characterization process: The FlexiForce Characterization Kit.

This kit was developed to save engineers and designers’ time constructing loading fixtures or create/debug circuitry for characterization.

This Short Video Shows How to Perform Linearity, Hysteresis, Drift, and Repeatability Tests with the FlexiForce Sensor Characterization Kit

What are Other Core Phases of FlexiForce Sensor Integration?

Sensor characterization is the first phase in a 6-phase sensor integration process that is applicable to any FlexiForce-embedded application. If you’d like to learn more, this free eBook “The 6 Phases of Force Sensor Integration” covers all phases in the design of a smart, force-sensitive medical device that incorporates FlexiForce sensors as a critical part to its functionality. You’ll see just how important it is to follow each step of the FlexiForce sensor integration process to ensure an efficient path to a successful design.

Whether you’re in the early stages of evaluating force sensor technology, or would like to speak to an applications engineer about your specific project, contact us today!